Last Updated on January 3, 2023 by Kevin Chen

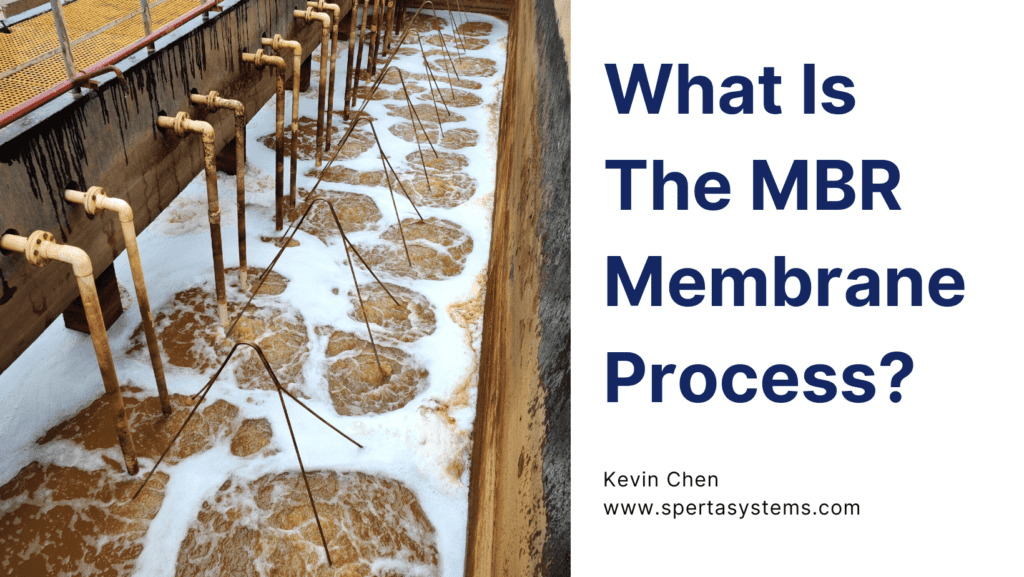

The MBR Membrane process combines membrane separation technology with bioreactors for sewage treatment. It not only saves the construction of the secondary sedimentation tank but also greatly improves the efficiency of solid-liquid separation. At the same time, due to the increased concentration of activated sludge in the aeration tank and the appearance of special bacteria (especially dominant bacteria) in the sludge, the biochemical reaction rate is improved. By reducing the F/M ratio to reduce the amount of excess sludge (even to zero sludge), it solves many outstanding problems in the traditional activated sludge process.

What are the features of the MBR Membrane Process?

Compared with traditional biochemical water treatment technology, the MBR Membrane process has the following 6 features:

- Efficient solid-liquid separation, the separation effect is much better than that of traditional sedimentation tanks, the effluent water quality is good, and the suspended solids and turbidity of the effluent are close to zero. They can be directly reused, realizing the recycling of sewage.

- The high-efficiency retention effect of the MBR membrane makes microorganisms completely retained in the bioreactor, realizes the complete separation of the hydraulic retention time (HRT) and the sludge retention time (SRT) of the reactor, and the operation control is flexible and stable.

- Because MBR combines the traditional wastewater treatment aeration tank and secondary sedimentation tank into one, and replaces all the process facilities of tertiary treatment, it can significantly reduce the floor space and save the civil construction investment.

- It is beneficial to the interception and reproduction of nitrifying bacteria, and the system has high nitrification efficiency. By changing the operation mode, it can also have the functions of ammonia removal and phosphorus removal.

- Since the sludge age can be very long, the degradation efficiency of refractory organic matter is greatly improved.

- The reactor operates under high volume load, low sludge load and long sludge age, and extremely low residual sludge output. Since the sludge age can be infinitely long, theoretically, it can realize zero sludge discharge.

The above is the information about the MBR Membrane process. If you still have questions about the membrane bioreactor or need to purchase MBR membranes, don’t hesitate to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components and has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.