Last Updated on August 7, 2023 by Kevin Chen

Membrane Bioreactor (MBR) technology has revolutionized the field of wastewater treatment. By combining conventional activated sludge treatment with advanced membrane filtration, MBR systems offer a range of benefits, including superior effluent quality, compact design, and enhanced nutrient removal capabilities. Thanks to its efficiency and versatility, this technology has been widely adopted across various sectors, from municipal wastewater treatment to industrial applications.

However, like any technology, MBR systems have challenges. One of the most significant issues faced in the operation of MBR systems is membrane fouling. This phenomenon, which involves the accumulation of suspended solids, microorganisms, and other substances on the membrane surface or within its pores, can significantly impact the performance and efficiency of the system.

Understanding membrane fouling, its causes, impacts, and how to mitigate it is crucial for the optimal operation of MBR systems. This blog post delves into the intricacies of MBR membrane fouling, providing a comprehensive guide to this critical aspect of wastewater treatment.

What is MBR Membrane Fouling?

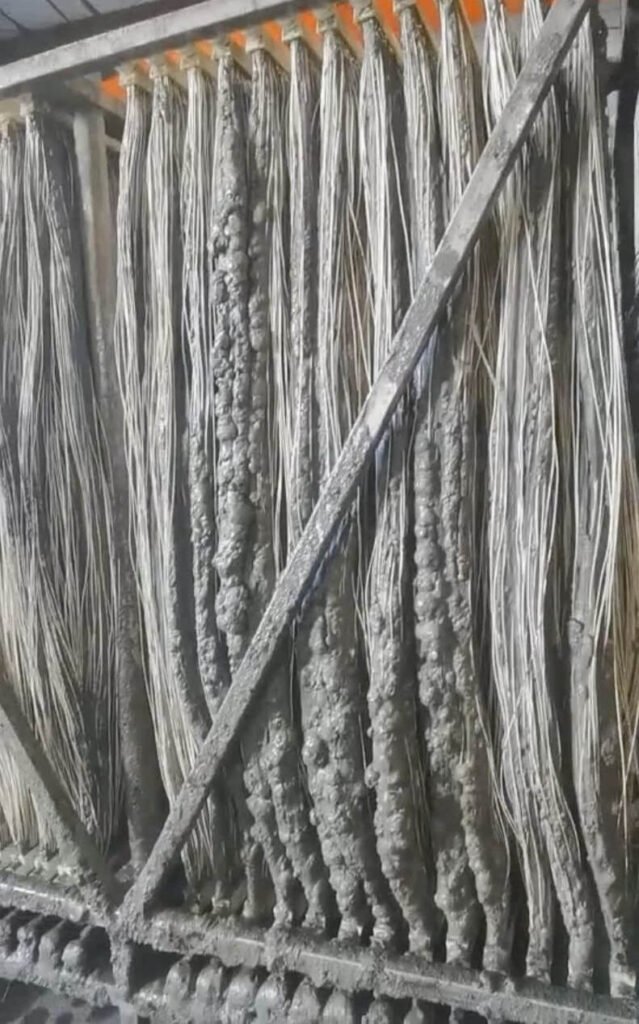

Membrane fouling in MBR systems is a complex process involving accumulating various substances on the membrane surface or within its pores. These substances include suspended solids, colloids, microorganisms, and organic and inorganic compounds. Over time, these materials can form a layer on the membrane surface, known as a cake layer, or penetrate the membrane pores, leading to pore blockage.

The fouling process typically begins with the adsorption of macromolecules onto the membrane surface, followed by the deposition and accumulation of suspended solids and colloids. Microorganisms present in the wastewater can then attach to this layer, forming a biofilm. This biofilm can further trap suspended solids and colloids, exacerbating fouling.

Various factors, including the wastewater’s characteristics, the MBR system’s operational conditions, and the membrane’s properties, can influence the rate and extent of membrane fouling. Understanding these factors is key to managing and mitigating membrane fouling in MBR systems.

Causes of MBR Membrane Fouling

Membrane fouling in MBR systems can be attributed to a combination of biological, physical, and chemical factors and operational parameters.

Biological Causes

The biological components of wastewater, mainly bacteria and extracellular polymeric substances (EPS), play a significant role in membrane fouling. Bacteria can attach to the membrane surface and form biofilms, trapping other particles and exacerbating fouling. EPS, which are complex mixtures of proteins, polysaccharides, and other biological compounds produced by bacteria, can also contribute to fouling by promoting the adhesion of bacteria and other particles to the membrane surface.

Physical and Chemical Causes

Suspended solids and colloids present in the wastewater can deposit on the membrane surface and block the membrane pores, leading to biological fouling. Organic and inorganic compounds can also interact with the membrane material and cause chemical fouling.

Operational Causes

Certain operational parameters of the MBR system can influence the rate and extent of membrane fouling. For example, the aeration rate can affect the scouring of the membrane surface and the dispersion of particles in the wastewater. The sludge retention time (SRT) and hydraulic retention time (HRT) can influence the concentration of solids and the system’s biological activity, which can affect fouling.

Impacts of Membrane Fouling

Membrane fouling in MBR systems can have several detrimental impacts, affecting not only the performance of the system but also its operational efficiency and cost-effectiveness.

Impact on Membrane Performance and Effluent Quality

Fouling can lead to a decline in membrane performance, decreasing permeate flux (the rate water passes through the membrane) and increasing transmembrane pressure. This can affect the quality of the treated effluent, making it harder to meet regulatory standards and potentially limiting the reuse applications of the treated water.

Increase in Energy Consumption and Operational Costs

The decline in permeate flux due to fouling can necessitate an increase in the operating pressure of the system to maintain the desired flow rate, leading to higher energy consumption. Furthermore, the need for frequent membrane cleaning or replacement due to severe fouling can result in increased operational costs.

Reduction in Membrane Lifespan

Persistent and severe fouling can lead to physical and chemical damage to the membrane, reducing its effective lifespan. This increases the costs associated with membrane replacement and impacts the MBR system’s overall sustainability.

How to Prevent or Solve Membrane Fouling Issues?

Membrane fouling is a significant challenge in MBR systems, but various strategies can be employed to mitigate its effects. These strategies aim to either prevent the fouling from occurring or to manage it once it has happened.

Preventive Measures

These involve modifying the operational parameters of the MBR system to create conditions that are less conducive to fouling. For instance, optimizing the aeration rate can help keep the membrane surface clean by creating turbulence that discourages the accumulation of foulants. Similarly, adjusting the sludge retention and hydraulic retention times can influence the system’s biological activity and, thus, the potential for biological fouling.

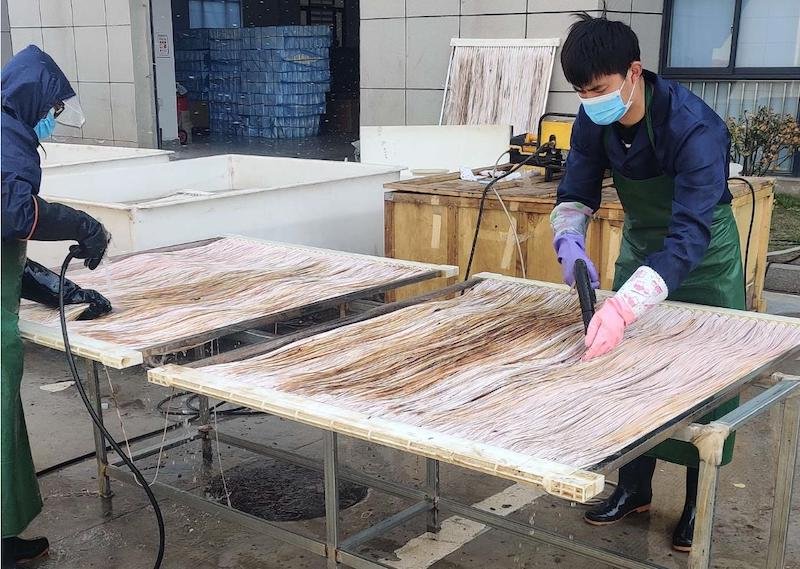

Cleaning Procedures

Regular cleaning of the membranes can help remove foulants and restore the system’s performance. Cleaning procedures can be physical, such as backwashing, air scouring, or chemical, involving cleaning agents to dissolve or dislodge the foulants.

Membrane Material and Design

The choice of membrane material and the design of the membrane module can also influence fouling. Some materials are more resistant to fouling than others, and specific design features can help reduce the accumulation of foulants on the membrane surface.

Use of Fouling-Resistant Membranes

Advances in membrane technology have led to the development of fouling-resistant membranes. These membranes have special coatings or are made from materials that resist the adhesion of foulants, thereby reducing the extent of fouling.

Feed Water Pretreatment

Pretreating the feed water to remove potential foulants before it enters the MBR system can also be an effective strategy. This can involve processes like coagulation, flocculation, or sedimentation.

By implementing these strategies, it is possible to manage membrane fouling in MBR systems effectively, maintaining system performance and extending the lifespan of the membranes.

Case Study: Successful Fouling Control in Practice

Consider the case of the Qingling River Wastewater Treatment Plant (WWTP) located in Wuhan City, a bustling urban area with over 150,000 residents. The plant was designed to handle a capacity of 30,000 cubic meters per day, but with the city’s rapid growth, the plant was facing increasing challenges.

One of the most significant issues was membrane fouling. The plant was using an older generation of MBR technology, and the frequent fouling was leading to increased operational costs, reduced membrane lifespan, and compromised effluent quality.

The plant management decided to implement a comprehensive fouling mitigation strategy. They started by thoroughly analyzing the wastewater to identify the main contributors to fouling. The results showed a high concentration of bacteria, extracellular polymeric substances, and suspended solids and colloids.

Based on these findings, the plant took several steps to address the issue. They adjusted operational parameters, including increasing the aeration rate and reducing the hydraulic retention time. They also introduced regular membrane cleaning and maintenance into their routine, using physical and chemical cleaning methods.

In addition, the plant decided to upgrade its MBR membranes to SPERTA’s advanced MBR membranes, known for their superior anti-fouling properties. These membranes were more resistant to the types of fouling agents found in their wastewater, significantly reducing fouling incidents.

The results were impressive. Within six months, the plant saw a 30% improvement in effluent quality, a 20% reduction in energy consumption, and a 50% reduction in cleaning and maintenance costs. The lifespan of the membranes also increased significantly, further reducing the plant’s operational costs.

The Future of Membrane Fouling Control

As we look to the future, the MBR membrane fouling control field is ripe with potential. With ongoing research and development, we expect significant advancements in this area.

New Membrane Materials and Coatings

One promising area of research is the development of new membrane materials and coatings that can resist fouling. For example, using hydrophilic coatings can reduce the adhesion of foulants to the membrane surface, thereby reducing fouling.

Optimization of Operational Parameters

Another area of interest is the optimization of operational parameters. By fine-tuning parameters such as aeration rate and sludge retention time, it may be possible to reduce fouling further and improve the efficiency of MBR systems.

Advanced Cleaning Methods

Finally, there is a growing interest in using advanced cleaning methods, such as ultrasonic cleaning and using enzymes or other biological agents, to remove foulants from the membrane surface.

While these are just a few examples, they illustrate the exciting possibilities for the future of MBR membrane fouling control. As we continue to innovate and push the boundaries of what is possible, we expect to see even more effective and efficient solutions for fouling management in the coming years.

Conclusion

In conclusion, membrane fouling is a significant challenge in the operation of MBR systems. It’s a complex issue that arises from various biological, chemical, and operational factors. The impacts of fouling are far-reaching, affecting membrane performance, effluent quality, energy consumption, operating costs, and the lifespan of the membrane.

However, understanding the causes and impacts of fouling is the first step toward effective fouling control. Various strategies, from optimizing operational parameters to implementing advanced cleaning methods, can help mitigate fouling. The case study of the wastewater treatment plant in the Netherlands demonstrates that with the right approach, it’s possible to manage fouling successfully and maintain the efficiency of MBR systems.

Looking ahead, the future of fouling control is promising. Ongoing research and technological advancements, such as developing new membrane materials and coatings, pave the way for more effective and sustainable solutions to fouling.

Ultimately, the goal is to harness the full potential of MBR technology in wastewater treatment, and effective fouling control is a crucial part of this endeavor. As we continue to improve our understanding of fouling and develop better strategies to combat it, we move closer to this goal.

Remember, at SPERTA, we are committed to providing high-quality MBR membranes and offering comprehensive support to our customers in managing fouling and other operational challenges. If you have any questions or need further assistance, don’t hesitate to get in touch with us. Let’s work together towards cleaner water and a more sustainable future.