MBR membrane has a good effluent quality and significant treatment effect and is often used in advanced sewage treatment. During operation, the MBR membrane may be damaged or polluted due to improper operation or other reasons, so it is necessary to make the replacement. Many clients are not sure when and how to replace the MBR membrane. This article will give you a brief introduction.

When to Replace the MBR Membrane?

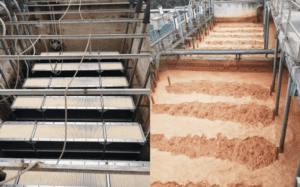

Usually, MBR membrane operation is very stable, and taking the membrane out of the membrane module for maintenance is unnecessary. However, a serious operational error, such as the MBR membrane being scratched by large particles, may cause pollution and damage to the MBR membrane. If the effluent water quality still fails to meet the requirements after several times of immersion and cleaning. It is time to take the membrane out from the module for replacement.

How to Judge the Damage Degree of the MBR Membrane?

- Check whether the flux of each MBR membrane module changes significantly under a specific pressure difference. If the flux is lower than the original design flux by more than 20%, then the membrane module is damaged.

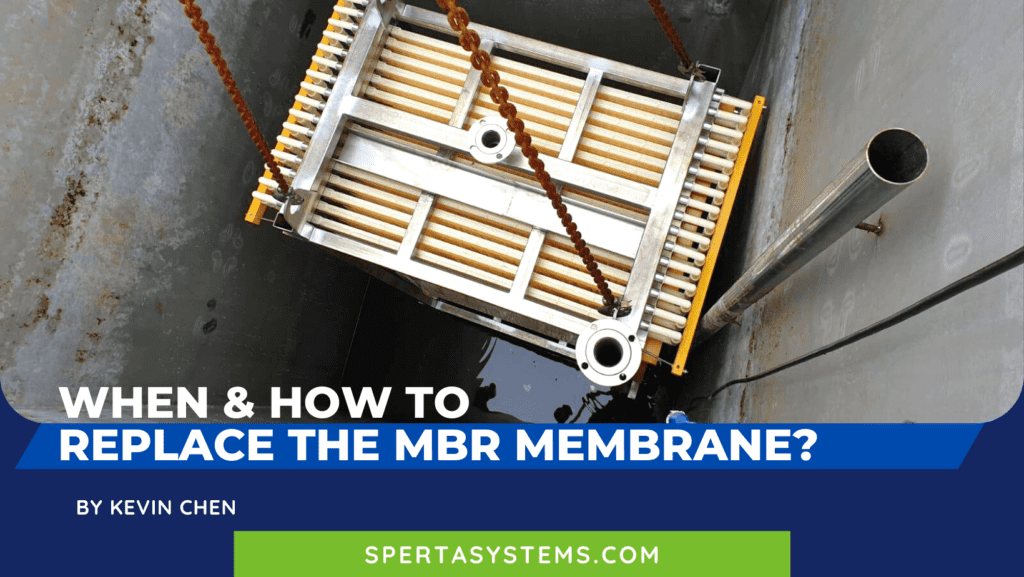

- Lift the damaged module out of the water, and ensure the highest part of the module is exposed to the water surface. Or lower the water level to the upper part of the module. The other membrane modules can operate normally.

- Separate the water collection pipe and the branch pipe in the membrane module and take out the MBR membrane one by one, check the cause, and start maintenance.

How to Replace the MBR Membrane?

Generally speaking, the possibility of damage to the entire MBR membrane is small. In most cases, only some fibers are damaged. At this time, the damaged membrane needs to be replaced. Please take special care not to lose any spare parts from the module when removing the entire MBR membrane and switching on the new one.

Put the MBR membrane into the module, connect different pipes, adjust the valve, wait for the whole module to be immersed in the water, and start rerunning the system.

Precautions

- The replacement of the sealing ring and the fixing bolts on the frame must be firm to avoid loosening or damage. It is recommended to check the connecting accessories every 3 months.

- We provide the accessories freely on the module to all our clients. For any special requests, please inform us when ordering the MBR membranes.

The above information shows that when the MBR is damaged or polluted, it must be replaced. And we should follow the replacement process to avoid unnecessary troubles. Regular cleaning of membrane modules can extend the service life of MBR membranes and reduce the replacement frequency.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has its own MBR membrane technology, a complete technical team, and pre-sales and after-sales service. If you have any needs or any other related questions, don’t hesitate to contact SPERTA.