What is Hydraulic Retention Time (HRT)?

Hydraulic Retention Time (HRT) is a term used in water treatment processes, referring to the average time that wastewater remains in a reactor, essentially the average reaction time between the wastewater and the microorganisms in the biological reactor. For biological treatment, HRT must meet specific process requirements; insufficient HRT leads to incomplete biochemical reactions and weaker treatment, while too long HRT can cause sludge aging.

| Process | Grit Chamber | Sedimentation Tank | Anaerobic Phosphorus Release | Denitrification | Aerobic Degradation | Aerated Biological Filter |

| HRT | 30~60s | 2~4h | 1h | 0.5~2h | 4~6h | 0.6~1.5h |

When treatment effectiveness is suboptimal, HRT should be checked against design values, including sludge recirculation volume, in the calculation. If HRT is too short, reduce the wastewater volume slowly; if it is too large, increase it gradually. Changes in wastewater volume should be gradual to avoid shock loads to the system; adjustments should primarily be made in recirculation volume rather than reducing wastewater inflow due to the challenging nature of wastewater treatment tasks.

In traditional activated sludge processes, HRT significantly influences the degree of wastewater treatment as it determines the sludge retention time.

How to Calculate HRT?

There are two types of hydraulic retention times in wastewater treatment: nominal HRT and actual HRT.

- 1. Nominal HRT

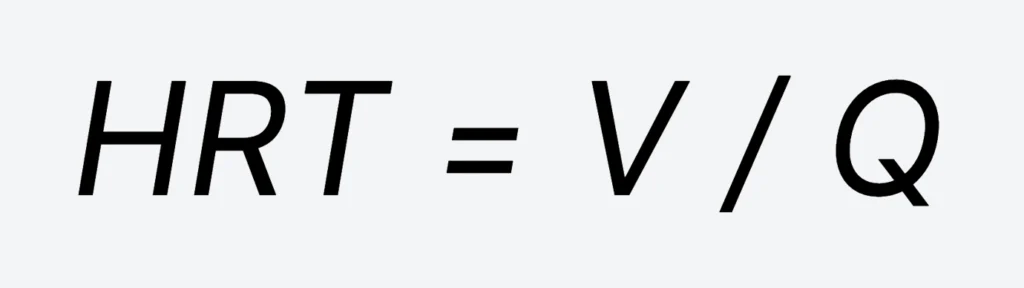

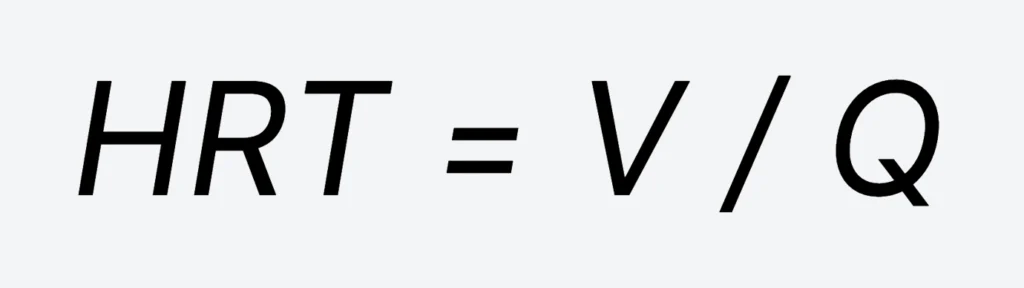

Nominal HRT is calculated as per the definition, i.e., HRT equals the effective volume of the wastewater treatment system divided by the inflow rate:

If the effective volume of the wastewater treatment system is V (m³), and Q is the inflow rate per hour (m³/h), then the formula for HRT is: HRT = V / Q

- 2. Actual HRT

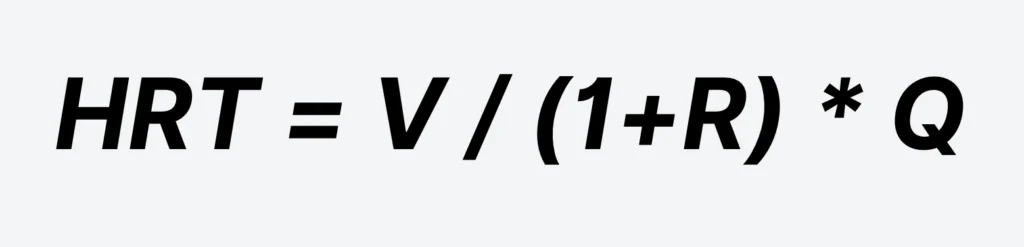

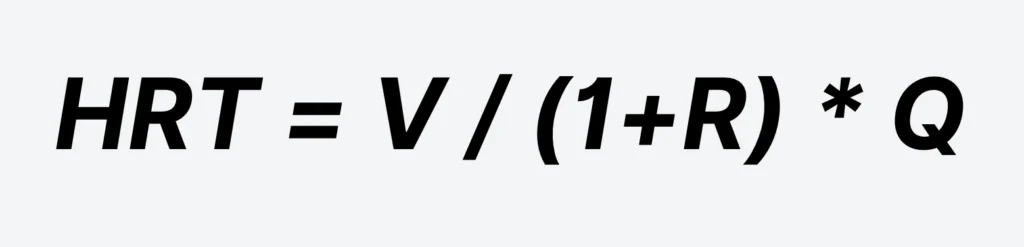

Actual HRT considers the actual stay of wastewater in the treatment system, including the volume of sludge recirculation:

If the effective volume of the wastewater treatment system is V (m³), Q is the inflow rate per hour (m³/h), and R is the sludge recirculation ratio, then the formula for HRT is: HRT = V / (1+R) * Q

What is the Impact of HRT on Denitrification?

The A²/O process shows excellent removal of NH₃-N under longer HRT conditions. Too short HRT does not allow sufficient growth time for various microbial populations, leading to rapid sludge loss and incomplete nitrification and denitrification reactions. When HRT reaches a certain value sufficient for reactions to occur fully in each reactor, increasing HRT further only adds an economic burden without significantly improving denitrification.

However, studies on membrane bioreactor composite processes indicate that within the selected HRT range (4.97 h-8.7 h), the system’s TN removal rate increases as HRT decreases. This is because longer HRT conditions lower the system’s organic loading rate, intensifying endogenous respiration and affecting sludge activity, ultimately reducing pollutant removal efficiency. Lowering HRT increases the organic loading rate, thereby enhancing the system’s denitrification capacity and improving nitrogen treatment.

What is the Impact of HRT on Phosphorus Removal?

Research on the A²/O process shows that increasing HRT does not necessarily improve TP removal rates; instead, it follows a trend of initially increasing and then decreasing. The highest TP removal rate and best removal effect occur at an HRT of 8 hours; when the HRT increases to 12 hours, TP removal rates decline, worsening phosphorus removal. Increasing HRT gradually reduces TP removal rates and can adversely affect TP removal. This may be due to excessive HRT causing sludge bulking. With a fixed carbon source, nitrifying bacteria compete intensely with polyphosphate-accumulating organisms (PAOs). Since PAOs have lower survival capabilities than nitrifying bacteria, this competition can lead to PAO death, hindering phosphorus uptake. Therefore, as HRT increases, the improvement in TP removal rates diminishes.

Conclusion

Hydraulic Retention Time (HRT) plays a crucial role in the effectiveness of wastewater treatment processes, impacting denitrification and phosphorus removal. Proper management of HRT can optimize the interaction between wastewater and treatment system microorganisms, ensuring efficient pollutant removal. While nominal HRT provides a basic understanding of wastewater stay in the system, actual HRT, which includes sludge recirculation, offers a more accurate measure for optimizing treatment processes. Balancing HRT is essential for maintaining system efficiency, preventing sludge aging, and avoiding excessive economic burdens. As such, careful calculation and adjustment of HRT are vital for achieving optimal wastewater treatment outcomes.

The above is the information about the HRT in wastewater treatment. If you still have related questions about the HRT calculation, please feel free to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has its own MBR membrane technology, a complete technical team, and pre-sales and after-sales service. If you have any needs, please feel free to contact us.