Last Updated on July 24, 2022 by Kevin Chen

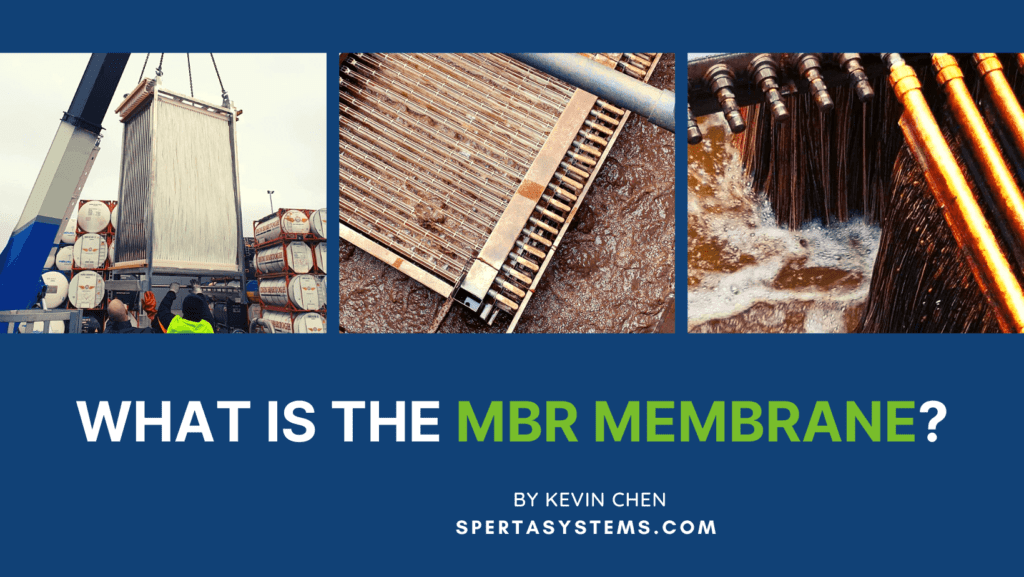

MBR membrane is a new type of water treatment technology equipment. It mainly comprises two technologies: MBR membrane separation and biological treatment. MBR membrane is a frequently used equipment in industrial water treatment and plays an essential role in urban sewage treatment.

The Features of MBR Membrane

Small Footprint

The MBR membrane process largely improves the sludge concentration and saves footprint by eliminating the need for the secondary sedimentation tank.

Easy Operation & Maintenance

The MBR membrane process performs sludge-water separation through membrane suction, which improves the traditional aerobic activated sludge treatment process, reduces the impact of sludge expansion on the membrane, and is highly automated and easier to operate.

Long Sludge Retention Time

The separation of MBR membranes makes the large molecule hard-to-degrade components in the wastewater stay in the bioreactor long enough to improve the degradation rate of hard-to-degrade organic matter. Due to its long sludge retention time, the MBR membrane is more suitable for microbial growth and removal of difficult organic matter from wastewater.

Stable Water Quality

MBR membrane can retain almost all microorganisms, especially for some difficult to precipitate, slow reproduction microbial groups, so it makes the biological and its richness in the bioreactor system, activated sludge domestication, shortening the incremental process, system treatment depth and impact resistance can be enhanced to ensure stable effluent quality and high transparency. MBR membrane can retain almost all microorganisms, especially for difficult-to-precipitate and slow-reproducing microorganism groups. Therefore, the organisms in the bioreactor system are enriched, the activated sludge is acclimated, the incremental process is shortened, the treatment depth and impact resistance of the system are enhanced, the effluent quality is stable, and the transparency is high.

Strong Impact Resistance

When the influent water volume changes greatly in a short time, the flow rate of the membrane can be increased in a short time to alleviate the impact. When the influent water quality changes, due to the high sludge concentration in the system, the purpose of relieving the impact can be achieved within a certain range.

The Application of the MBR Membrane

Domestic Sewage Treatment

Municipal wastewater, to achieve sewage treatment nearby, saving time and improving efficiency, while preventing pollution caused by long-distance transportation of sewage, treatment of industrial wastewater, and secondary development and utilization. We can use the treated water for greening, flushing, supplementing ornamental water, and other non-drinking purposes.

Drinking water treatment

The MRB system is a very convenient way to build a barrier to prevent bacteria and viruses from entering the water supply terminal. The MBR system in the ultrafiltration membrane can remove bacteria up to 61og and viruses up to 41og, meeting drinking water treatment standards.

Surface Water Treatment

We can use the MBR for surface water treatment. The treated water can be used for irrigation or as feed water for reverse osmosis to prepare pure water.

Seawater desalination pretreatment

Seawater production of fresh water usually uses reverse osmosis desalination technology. MBR system combined with sub-osmosis technology can better control seawater quality, provide high quality to the reverse osmosis system to ensure the stable operation of the reverse osmosis system, and improve the efficiency of desalination.

The above is the information about the MBR membrane. If you still have related questions about the membrane bioreactor, please feel free to contact SPERTA.