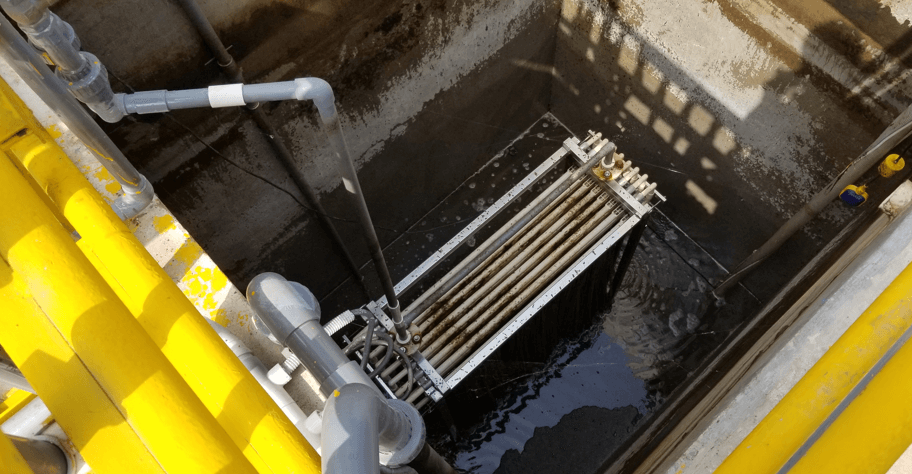

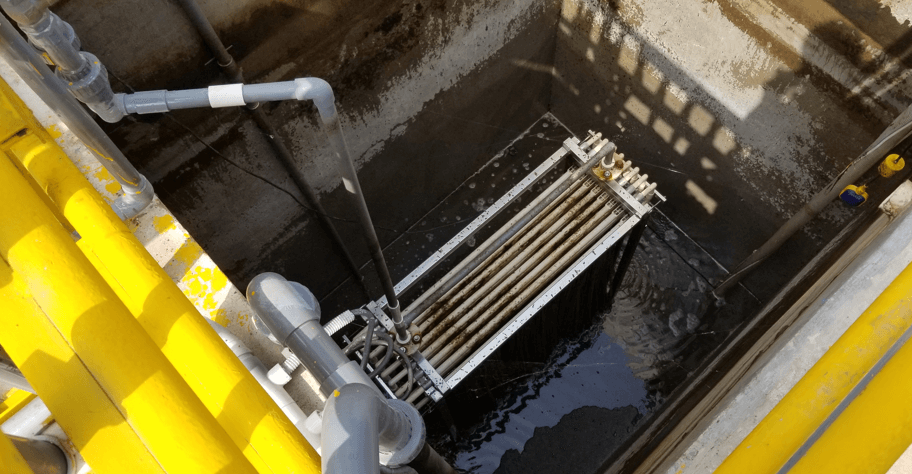

MBR membrane has an immersed curtain-type structure, which is different from the spiral-wound type membrane. However, the material of the MBR membrane is the same as that of spiral-wound type nanofiltration and ultrafiltration membrane, which is PVDF material. Therefore, we can use the same cleaning agents. This article will give you a brief introduction to the cleaning agents for MBR membranes.

We can select the cleaning agent for the MBR membrane according to the type of pollutants on the membrane surface. Common MBR membrane pollutions include:

- Inorganic salt scaling (calcium carbonate, magnesium sulfate, and other substances incompatible with water).

- Iron filings, colloidal substances.

- Algae, viruses, bacteria, and other organisms.

- Macromolecular organic matter (protein, carbohydrate) and so on.

Below are cleaning agent recommendations for different contaminants:

- Inorganic salt scale: preferred 0.2% hydrochloric acid solution; 2% citric acid solution, 1% sodium sulfate solution, or 0.5% phosphoric acid solution are optional.

- Metal compounds: preferred 1% sodium sulfate solution; 2% citric acid solution, 0.5% phosphoric acid solution are optional.

- Acid-insoluble scaling: 0.1% sodium hydroxide solution + 1% EDTA tetrasodium concentrate

- Inorganic colloid: 0.1% sodium hydroxide solution + 0.025% sodium dodecyl sulfonate solution

- Microbial and organic pollution: 0.1% sodium hydroxide solution + 0.025% sodium dodecyl sulfonate solution

Common cleaning methods for MBR membranes

- Aeration cleaning: Rinse the MBR membrane with compressed air, make the fiber vibrate, peel off the polluted particles, and achieve the purpose of cleaning. Generally used for cleaning larger particles such as sludge.

- Water Backwashing: Pump the filtered water from the backwashing tank to the MBR membrane suction pipe to clean the impurities in the fiber pores. It generally needs to be cleaned regularly every day.

- Chemical backwashing: adding a chemical cleaning agent to clean MBR membrane, generally used to clean insoluble substances. Optional liquids include 1000 PPM sodium hypochlorite solution.

- Chemical offline cleaning: After long-term use of MBR membrane, conventional cleaning cannot recover the filtration performance. The MBR membrane equipment needs to be soaked in a special chemical solution (such as oxalic acid or sodium bisulfite) for 30-60 minutes to clean the microorganisms, inorganic salt structure grease, and other substances on the MBR membrane.

The above is a brief introduction to the MBR membrane cleaning agent. Before choosing a cleaning agent, it is recommended to consult the manufacturer that provides the relevant cleaning agent for technical guidance to avoid using chemical agents incompatible with the MBR membrane material or improper operation to damage the MBR membrane elements.