Last Updated on April 7, 2023 by Kevin Chen

Wastewater treatment is an essential process for protecting public health and the environment. As industries and populations continue to grow, so too does the amount of wastewater that needs to be treated. Conventional wastewater treatment methods have their limitations, and there is a need for new technologies that can improve the efficiency, quality, and cost-effectiveness of the process. One such technology is MBR membrane technology.

MBR membrane technology is a type of wastewater treatment technology that uses a membrane filtration process to separate solids and bacteria from wastewater. The technology has many advantages over conventional wastewater treatment methods, including improved effluent quality, reduced footprint, and lower operating costs.

What Are The Benefits of MBR Membrane Technology?

- Improved Effluent Quality

One of the primary advantages of MBR membrane technology is its ability to produce high-quality effluent. MBR membrane technology can remove suspended solids, bacteria, and other contaminants from wastewater, resulting in the effluent that meets or exceeds regulatory standards. This high-quality effluent can be used for a variety of purposes, including irrigation, industrial processes, and even potable water production.

- Reduced Footprint

Another advantage of MBR membrane technology is its reduced footprint. Conventional wastewater treatment methods typically require large treatment tanks and settling ponds to achieve the necessary level of treatment. On the other hand, MBR membrane technology can achieve the same treatment level in a much smaller footprint. This is because the membrane filtration process allows higher concentrations of solids and bacteria to be processed in a smaller area.

- Lower Operating Costs

In addition to improved effluent quality and reduced footprint, MBR membrane technology can also result in lower operating costs. The technology requires less energy and chemicals than conventional treatment methods, resulting in lower operational expenses. Additionally, the compact design of MBR membrane systems can reduce construction and maintenance costs.

- Customization and Flexibility

One of the benefits of MBR membrane technology is its customization and flexibility. We can customize the MBR systems to meet the specific needs of different wastewater treatment systems. For example, MBR systems can be designed to remove specific types of contaminants or to treat different volumes of wastewater.

Additionally, MBR membrane technology is flexible and can be tailored to different applications. MBR systems can be used as a standalone solution for wastewater treatment or as part of a larger treatment system. They can also be combined with other treatment technologies, such as UV disinfection or activated carbon filtration, to create a more comprehensive treatment solution.

How Does MBR Membrane Technology Work?

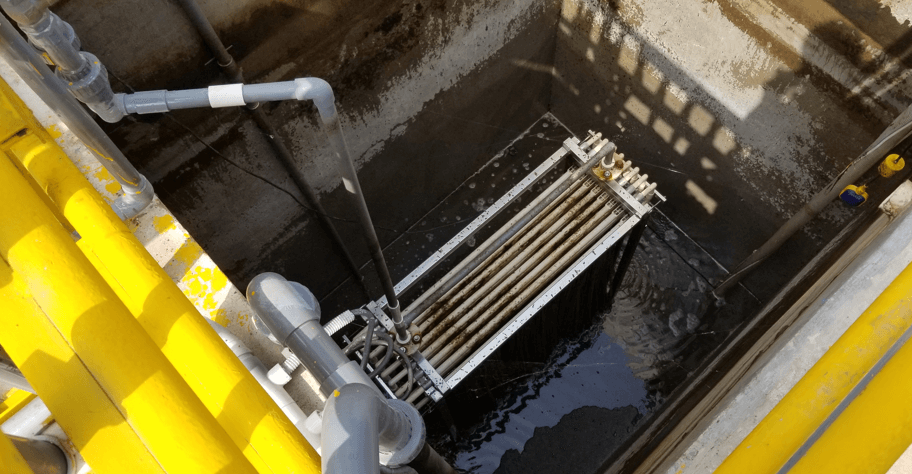

MBR membrane technology uses a membrane filtration process to separate solids and bacteria from wastewater. The process consists of three main steps: biological treatment, membrane filtration, and solids separation.

- Biological Treatment

In the first step of the process, wastewater is introduced into a biological reactor, where bacteria break down organic matter in the wastewater. This step is similar to conventional wastewater treatment methods.

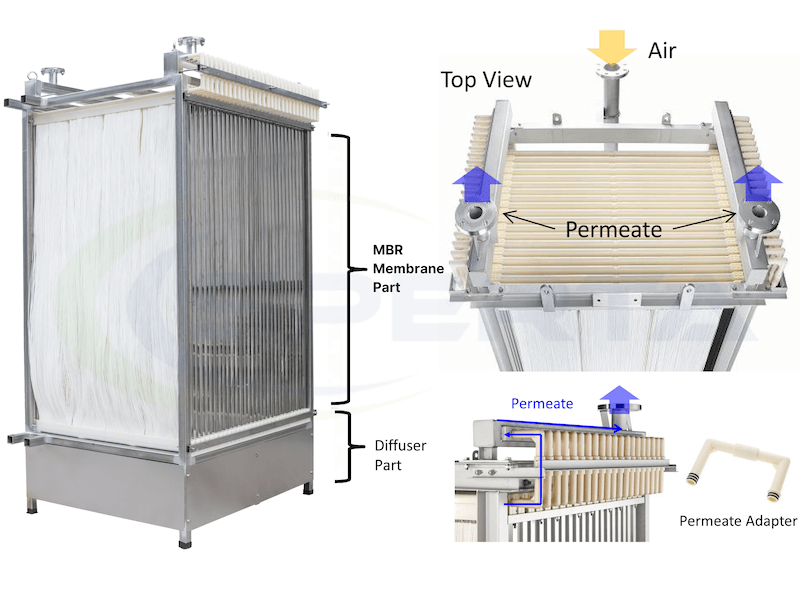

- Membrane Filtration

After biological treatment, the wastewater is fed into a membrane filtration unit. This unit contains a series of membranes that act as filters, allowing water and dissolved salts to pass through while retaining suspended solids and bacteria. The membranes can be made of various materials, including polymeric and ceramic materials.

- Solids Separation

The last step of the process is solids separation. The solids and bacteria retained by the membranes are concentrated and periodically removed from the system. The concentrated solids can be further treated or disposed of depending on the requirements of the specific wastewater treatment system.

What Are The Applications of MBR Membrane Technology?

MBR membrane technology has a wide range of applications, including municipal wastewater treatment, industrial wastewater treatment, and desalination.

- Municipal Wastewater Treatment

MBR membrane technology is increasingly being used for municipal wastewater treatment. Municipalities worldwide are upgrading their wastewater treatment systems with MBR membrane technology to meet regulatory standards, reduce costs, and improve efficiency. The technology benefits small- to medium-sized municipalities with limited space for treatment facilities.

- Industrial Wastewater Treatment

MBR membrane technology is also being used for industrial wastewater treatment. Many industries generate wastewater containing high levels of contaminants, making treatment challenging. We can customize the MBR membrane technology to meet the specific needs of different industries and can handle a wide range of pollutants, including heavy metals and oils.

- Desalination

We can also use MBR membrane technology for desalination, which removes salt and other minerals from seawater or brackish water to produce freshwater. The technology can be combined with other desalination methods, such as reverse osmosis, to improve the efficiency and cost-effectiveness of the process.

What Are the Considerations for Upgrading to MBR Membrane Technology?

Upgrading to MBR membrane technology requires careful planning and consideration. Factors to consider include system design, cost, and maintenance. MBR systems require regular maintenance to ensure the membranes function properly and prevent clogging or fouling. Additionally, MBR systems require specialized equipment and trained personnel to operate and maintain.

However, the benefits of upgrading to MBR membrane technology can outweigh the costs. MBR systems can improve the quality of effluent produced by wastewater treatment systems, resulting in cleaner water and fewer environmental impacts. Additionally, MBR systems can reduce the physical footprint of wastewater treatment systems, making them ideal for use in urban areas or locations with limited space.

Conclusion

In conclusion, MBR membrane technology offers a more efficient and cost-effective approach to wastewater treatment compared to traditional methods. MBR systems produce higher-quality effluent, require less physical space, and are more energy-efficient than traditional systems. Additionally, MBR membrane technology is customizable and flexible, making it suitable for a wide range of applications. While upgrading to MBR membrane technology requires careful planning and consideration, the benefits of improved wastewater treatment can result in significant environmental and economic benefits.

The above information is about upgrading the treatment process with MBR membrane technology. If you still have questions about the membrane bioreactor or need to purchase MBR membranes, don’t hesitate to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components and has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.