Last Updated on February 19, 2023 by Kevin Chen

The MBR membrane process is a membrane separation technology combined with the traditional activated sludge method, with a high-efficiency wastewater treatment capacity.

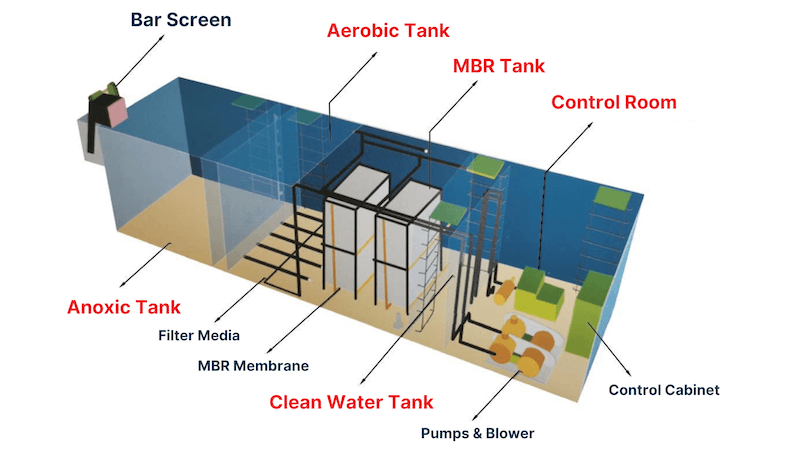

The MBR membrane can have such an efficient treatment capacity, which has a certain relationship with its treatment process. Generally, the MBR membrane treatment process is: Bar Screen → Adjusting Tank → Anoxic Tank → Aerobic Tank → MBR Tank → Clean water Tank → Discharge or Reuse.

What Is the Advantage Of the MBR Membrane Process?

MBR is a new type of wastewater treatment plant that combines ultra and microfiltration membrane separation technology with a biological reactor in wastewater treatment. This process combines the advantages of the MBR membrane and biological treatment technologies. It can completely replace traditional secondary sedimentation tanks. Compared to the conventional process, this MBR process has significant advantages.

Therefore, the membrane bioreactor (MBR) process greatly enhances the bioreactor function through membrane separation technology. It is one of the latest technologies for wastewater treatment.

What Are the Features Of the MBR Membrane?

MBR membrane bioreactor has the advantages of compact structure, beautiful appearance, small footprint, low operating costs, stable and reliable, high degree of automation, and easy maintenance & operation. The effluent quality of MBR wastewater treatment is better than the required standard. It is advanced equipment for treating wastewater.

The above is the information about the MBR Membrane process. If you still have questions about the membrane bioreactor or need to purchase MBR membranes, don’t hesitate to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components and has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.