Last Updated on July 24, 2022 by Kevin Chen

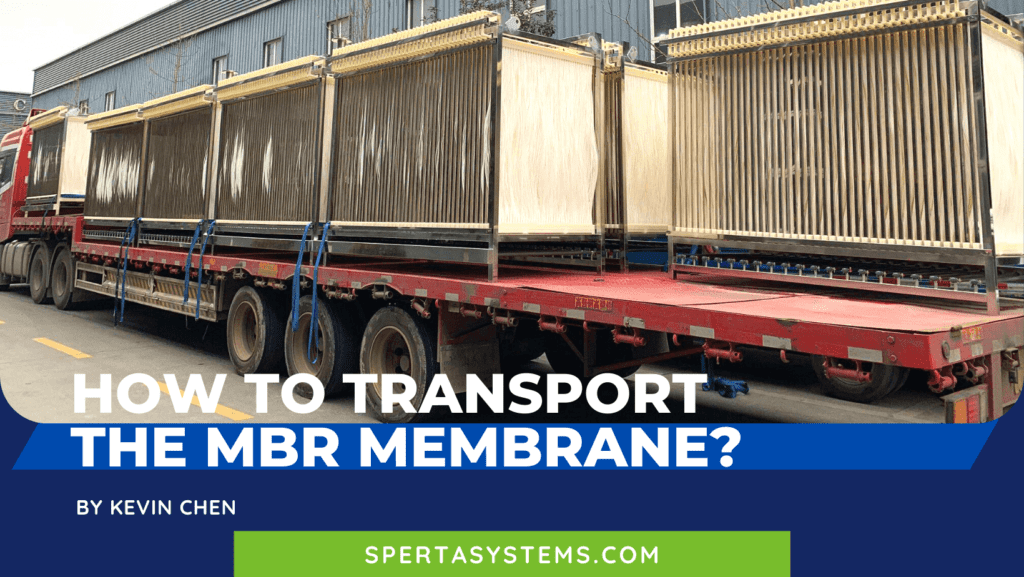

When we purchase the MBR membrane, it is usually transported by large trucks. We must understand some matters in advance in the transportation process, especially long-distance transit, to avoid damage to the MBR membrane element caused by the wrong operation. Next, I will introduce the precautions in transporting hollow fiber MBR membranes.

Precautions before Transporting MBR Membranes

- The truck compartment should be clean and tidy, and there should be no sharp tools such as knives to avoid damaging the package in transit.

- The hollow fiber MBR membrane must be tested for integrity and impact resistance before leaving the factory.

- The membrane elements should be placed in order; the same model should be put together. And we should check the quantities of MBR membrane elements before and after getting on the truck.

Precautions when Transporting MBR Membranes

- When leaving the factory, the MBR membrane will be filled with protective agents to keep the mbr moist and hydrophilic. The agents can also prevent the growth of microorganisms during storage and transportation.

- The MBR membranes are generally double-packed before leaving the factory, the inner packaging is plastic bags, and the accessories are individually packed.

- The MBR membrane should be transported flatly to avoid the collision, rain, exposure, and freezing, and the maximum number of stacked layers shall not exceed 6.

- The MBR membranes that are not used temporarily should be stored on a flat, clean floor. During storage, pay attention to moisture-proof and avoid direct sunlight. We should control the storage environment temperature at 5 to 40 °C;

- The MBR membrane has been treated with anti-corrosion before leaving the factory. It can effectively prevent the growth of bacteria during short-term storage, but it is not suitable for long-term storage. The longest storage time we advise is not more than 3 months.

- The hollow fiber MBR membrane module must be stored in a wet state at all times. Once dehydrated and dried, it will cause irreversible attenuation of membrane flux and significantly reduce water production.

The above are the relevant precautions for transporting hollow fiber MBR membranes. If you have any relate question, do not hesitate to contact SPERTA.

Post Views: 391