Last Updated on August 30, 2022 by Kevin Chen

The MBR Membrane is a type of water treatment that is becoming increasingly popular in various industries. MBR Membranes can remove suspended solids, bacteria, viruses, and other contaminants from water, making it safe to discharge. In this article, we will explain the steps you need to take to ensure successful commissioning.

How To Commission The MBR Membrane With Clean Water?

Step 1: Ensure the air and water pipes are properly connected, and the joints of the bolts are tightened.

Step 2: Check whether the automation of blowers and production pumps meets the requirements.

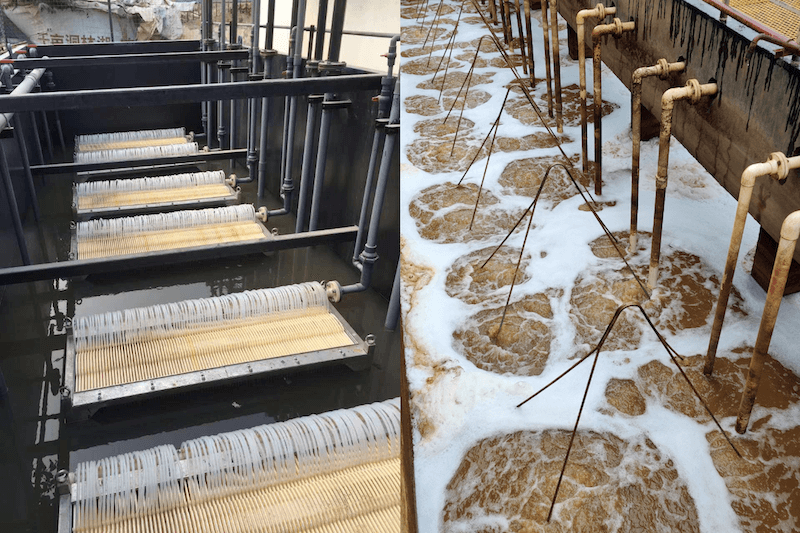

Step 3: Open the air exhaust valve to remove the air from the MBR membrane element.

Step 4: Put clean water (tap or filtered) to the operational level.

Close the air exhaust valve.

Step 5: Confirm the aeration volume and aeration uniformity after turning on the air blower.

Step 6: When commissioning with the clear water, fill the production water pump and production water pipeline with water, start the production water pump and record the membrane suction flux, trans-membrane pressure difference, water temperature, etc.

Precautions:

- The membrane element must be soaked in water for more than 8 hours before starting the water production pump to produce water.

- The membrane must be kept in a moist state after clear water commissioning; a dry membrane will decrease water permeability.

The above is information about commissioning MBR membrane system with clean water. If you still have related questions about the membrane bioreactor, please feel free to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components and has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.