Last Updated on August 7, 2023 by Kevin Chen

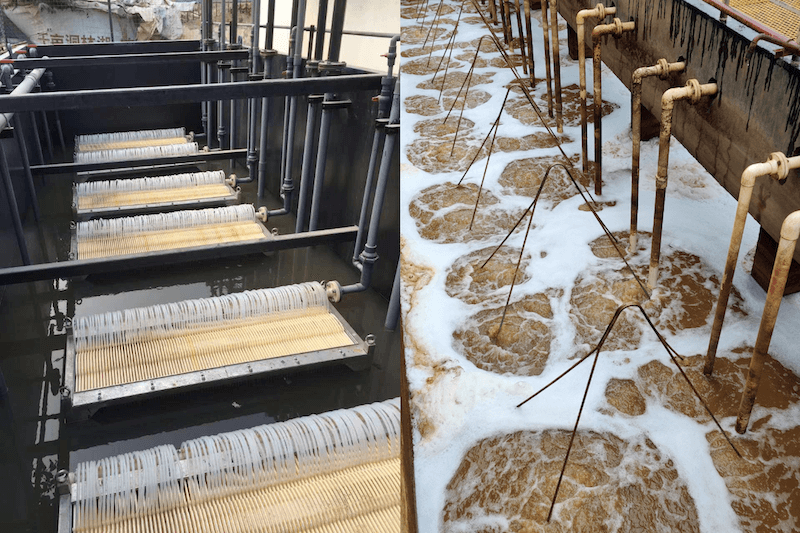

MBR (Membrane Bioreactor) is a widely used technology for wastewater treatment that combines biological processes and membrane filtration. However, one of the challenges of MBR operation is the development of negative pressure (or vacuum) in the membrane module, which can affect the system’s performance.

What Causes A High Negative Pressure In the MBR Membrane?

- Clogging: The accumulation of solids and/or biofilm on the membrane surface can reduce permeability and increase resistance to flow, decreasing pressure in the module.

- Air-binding: Entrapped air in the membrane module can cause bubbles to accumulate on the membrane surface, reducing permeability and creating negative pressure.

- Fouling: The accumulation of organic and/or inorganic substances on the membrane surface can also cause reduced permeability and create negative pressure.

How To Solve the High Negative Pressure In the MBR Membrane?

- Air scouring: Injecting air into the membrane module can help to dislodge any bubbles or particles that may be causing negative pressure.

- Backwashing: This involves reversing the direction of flow across the membrane to dislodge any accumulated solids or biofilm and to restore permeability.

- Chemical cleaning: Periodic cleaning with specialized chemicals can help to remove fouling and maintain membrane performance.

In conclusion, negative pressure in MBR systems can significantly impact system performance, and it is important to identify the root cause and implement appropriate corrective measures. By implementing proper maintenance and cleaning procedures, MBR systems can continue to provide reliable and effective wastewater treatment.

The above information is about upgrading the treatment process with MBR membrane technology. If you still have questions about the membrane bioreactor or need to purchase MBR membranes, don’t hesitate to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components and has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.