Last Updated on July 6, 2022 by Kevin Chen

The MBR membrane is a kind of wastewater filtration equipment that has been widely used in recent years. It combines the traditional filtration principle and updates it, using membrane separation technology and biochemical technology to filter the wastewater effectively.

What is the MBR Membrane Bioreactor?

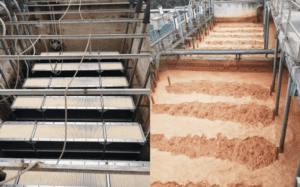

The MBR membrane bioreactor is a new type of wastewater treatment equipment that uses MBR membrane for sewage treatment. The MBR membrane module replaces the secondary sedimentation tank at the end of the traditional biological treatment technology so that the bioreactor maintains a high concentration of activated sludge, increases the organic load of biological treatment, and reduces the footprint of sewage treatment facilities. The MBR membrane modules immersed in the aerobic biological tank is used to intercept activated sludge and macromolecular organic matter, maintain a low sludge load, and reduce the amount of excess sludge in the membrane tank.

The equipment has good effluent quality, low operating cost, strong system impact resistance, low sludge volume, high degree of automation, small footprint, and easy integration. It can be used not only as a small sewage reuse equipment but also as the core treatment unit of a large sewage treatment plant.

How does MBR Membrane Work?

MBR has a unique structure. The MBR membrane module is placed in the aeration tank, and a pump filters out the water after aerobic aeration and biological treatment through the membrane. The MBR membrane intercepts the activated sludge and macromolecular organic substances in the biochemical reaction tank. It directly replaces the secondary sedimentation tank. The refractory substances are continuously reacted and degraded in the reactor. At the same time, the concentration of activated sludge is greatly increased, and the hydraulic retention time and sludge retention time in the membrane tank can be controlled by manual setting time.

The MBR membrane greatly improves the solid-liquid separation capability of the entire sewage treatment system, so the effluent water quality and volume load are greatly improved. The water quality after membrane treatment meets the reuse standard, and the water after disinfection is biologically safe.

The application of MBR membrane bioreactor in major fields is getting wider and wider. Still, it has certain limitations, such as higher energy consumption. With the progress of technology, the MBR membrane bioreactor will undoubtedly improve.

The above is the information about the MBR membrane bioreactor and how it works. If you still have related questions about the membrane bioreactor, please feel free to contact SPERTA.