Last Updated on July 4, 2025 by Kevin Chen

Introduction

Food processing creates large amounts of wastewater with high levels of pollutants. As regulations become stricter and water reuse becomes more important, food factories need better ways to treat their wastewater. MBR (Membrane Bioreactor) technology combines biological treatment and membrane filtration, offering an efficient solution to help food plants meet modern water quality standards.

Food Industry Wastewater: Main Challenges

Food processing plants produce wastewater that contains a lot of organic matter, grease, and suspended solids. The composition of the wastewater often changes, depending on the production process. These factors make it harder to treat the water effectively. At the same time, stricter discharge standards require food factories to remove more pollutants before releasing or reusing their wastewater.

How MBR Membranes Work?

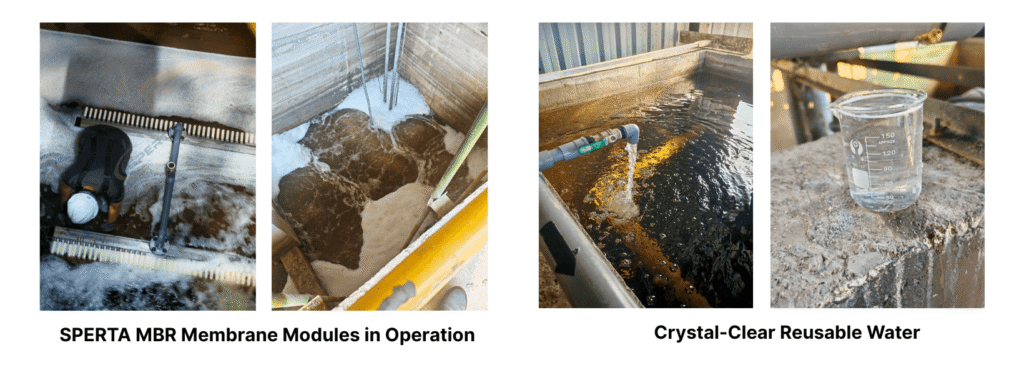

Membrane Bioreactor (MBR) technology combines biological wastewater treatment with membrane filtration. First, wastewater enters the bioreactor tank, where microorganisms naturally digest organic contaminants. After biological treatment, the mixed liquid is drawn through ultra-fine membranes. These membranes act as physical barriers, capturing suspended solids, bacteria, and pathogens, resulting in clear, high-quality treated water.

Standard MBR Process Flow for Food Industry Wastewater Treatment

The standard MBR process for food industry wastewater treatment starts with a bar screen to remove large solids, followed by an oil and grease separator to reduce fats that could harm the system. Wastewater then flows into an equalization tank to balance fluctuations in flow and pollutant levels. Optional PAC dosing may be applied to improve the removal of stubborn organic compounds. The water moves into a biological reactor where microorganisms break down organic matter, followed by membrane filtration that separates suspended solids and bacteria. Clean treated water is collected for discharge or reuse, while excess sludge is removed and treated separately. Regular membrane cleaning ensures long-term system efficiency and reliability.

Case Study

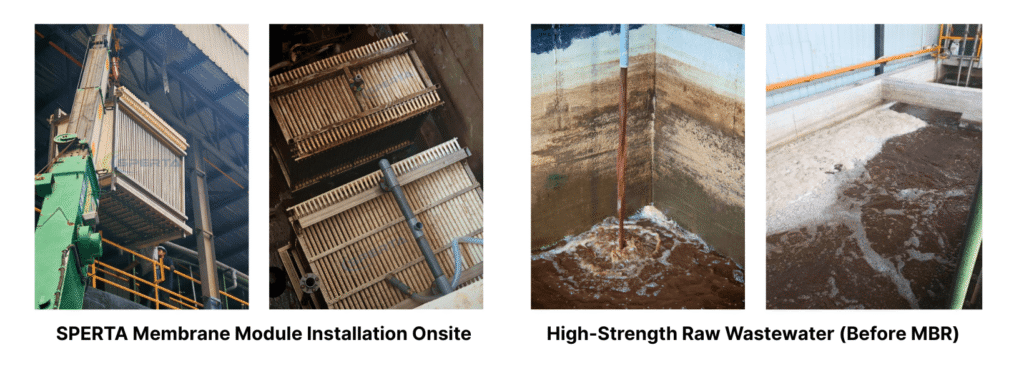

Sperta’s latest project showcases the advantages of MBR technology for food processing wastewater reuse. One of our clients in Malaysia — a leading food processor — previously used a conventional physical-chemical treatment system, including DAF (Dissolved Air Flotation). As environmental regulations became stricter, their treated effluent could no longer reliably meet new discharge standards or support the company’s increasing demand for water reuse.

To solve these challenges, Sperta provided an integrated MBBR + MBR solution. The upgraded system delivers excellent effluent quality suitable for water reuse, reduces operational and maintenance costs, and helps the client enhance their environmental compliance and reputation.

| Parameter | Unit | Before | After |

| COD | mg/L | 2064 | 62.5 |

| BOD | mg/L | 1083 | 9.95 |

| TSS | mg/L | 660 | 3 |

| Oil & Grease | mg/L | 51.5 | <0.5 |

| Ammonical Nitrogen | mg/L | 70.3 | 2.7 |

| Sulfide | mg/L | 3.84 | <0.0001 |

| Colour | ADMI | 617 | 10.3 |

Summary & Contact

MBR technology offers food industry facilities a reliable solution to their wastewater treatment challenges. It effectively handles high organic loads, provides stable performance, and ensures regulatory compliance. For further information on how MBR membranes can help your food processing plant, contact SPERTA technical team for a tailored solution and quotation.