Last Updated on July 24, 2022 by Kevin Chen

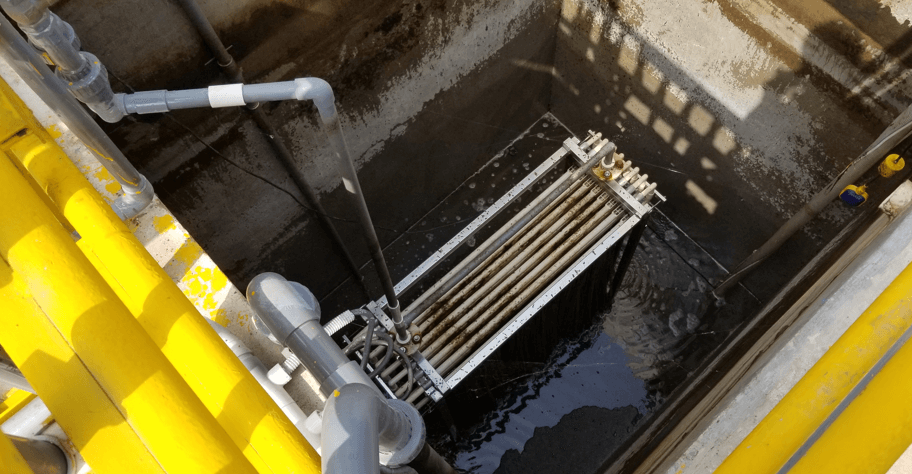

Membrane bioreactor (MBR) is a key component of any successful wastewater treatment plant. They play an important role in breaking down chemicals and removing pollutants from wastewater, making them an essential part of any water treatment facility. However, like all machines, MBR can wear out over time. When this happens, the plant’s ability to treat wastewater effectively decreases. So how often should the MBR membrane be replaced? And what should you do if it’s time to replace your MBR? In this article, we’ll answer these questions and more.

What Is the Service Life of the MBR Membrane?

The service life of MBR membranes is related to many factors, such as the raw water quality, pretreatment, operation condition, PH, temperature, and maintenance. Theoretically, MBR membranes can work properly for at least 3-5 years without problems.

How Often Should We Replace the MBR Membrane?

The service life of the mbr membrane is generally about 3-5 years. If the operating conditions are relatively good, it is possible to replace it after 8-10 years, mainly depending on the quality of the influent water and the operating environment. The quality of the MBR membrane is also the key. Cheap MBR membranes are not of good quality and can cause problems if used for a long time, so it is important to choose a good brand of MBR membrane like SPERTA.

What Affects the Service Life of MBR Membrane?

During installation and construction, debris (especially sharp debris) can enter the membrane system and damage the MBR fibers and membrane. We need to clean the tank before placing the MBR membrane modules inside.

Feed water temperatures below the design temperature (often found in seasonal changes) can reduce the drainage performance of the membrane. Changes in water contaminant types, concentrations, and water quality can also cause membrane permeability to be lower than expected. In order to solve these problems, the membrane system design must first consider the minimum water temperature and water quality fluctuation range during the year and allow for a margin of safety when selecting the MBR membrane area. Water temperatures above 45°C can shorten the life of the MBR membrane. Typically, we should keep water temperatures below 40°C, and cooling measures should be taken as needed.

Microorganisms, inorganic salt scale, grease, organic matter, and colloids can cause membrane fouling. The membrane performance will irreversibly degrade if it cannot be removed by chemical cleaning.

The above is the information about the service life of the MBR membrane and when we shall replace it. If you still have related questions about the membrane bioreactor, please feel free to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has its own MBR membrane technology, a complete technical team, and pre-sales and after-sales service. If you have any needs, please feel free to contact us.