As a tool across various industries, hollow fiber membranes are increasingly important for separation. It has versatile applications, making it a vital component of inefficient wastewater treatment. And hollow fiber membranes can ensure clean water. It also plays a crucial role in life-saving medical procedures.

Exploring the World of Hollow Fiber Membranes

Hollow fiber membranes have microscopic openings in their walls that essentially are porous tubes. These tiny pores are significant to their wide-ranging applications:

Water Purification: Behind many water purification systems, Hollow fiber membranes are the unsung heroes. They serve as barriers. And the barriers allow clean water to pass through while trapping impurities, bacteria, and particles. Household filters use this technology so we can drink clean water.

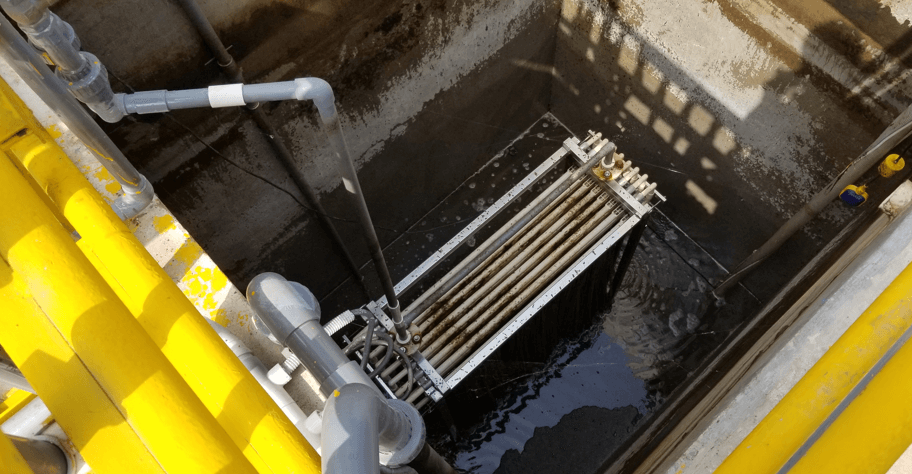

Wastewater Treatment: In wastewater treatment, hollow fiber membranes sparkle like a diamond. It can be used to separate contaminants from wastewater. It is its job to clean and recycle water sustainably. For industry and municipalities, this application to reduce their environmental footprint is important.

Dialysis: In the medical field, hollow fiber membranes can be used in kidney dialysis machines. They act as filters for the patient’s blood. They remove waste products and excess fluids from the blood. This life-saving process can not only help the patients with their health but also improve their well-being.

Food and Beverage Industry: For the food and beverage industry, hollow fiber membranes are very dependent. They are used in processes like clarification, concentration, and separation. These membranes ensure the clarity and concentrated flavor of the juice.

Pharmaceuticals: Pharmaceutical manufacturing demands strict purity standards. Hollow fiber membranes are utilized to filter and purify pharmaceutical products. These processes can ensure that medications and the highest quality standards are treated.

Gas Separation: We can find Hollow fiber membranes in gas separation processes. For example, they are used in air separation plants to produce high-purity nitrogen or oxygen.

Research and Laboratory Applications: Hollow fiber membranes always be used in research and laboratory settings. Scientists and researchers employ it for various filtration and separation tasks. These membranes provide a versatile and efficient means to conduct experiments. And scientists can analyze substances in this way.

The Endless Possibilities of Hollow Fiber Membranes

The hollow fiber membrane’s advantage is that it can adapt to various harsh environments. They can be customized to meet the unique requirements of different industries. Because of its efficiency and reliability, hollow fiber membranes have become the first choice for those seeking effective filtration and separation solutions.

How Can You Benefit from Hollow Fiber Membranes?

You may need cleaner drinking water, efficient wastewater treatment, or specialized filtration solutions. Hollow fiber membranes offer all kinds of possibilities when you are in trouble with your needs. Experienced membrane manufacturers are your best friend who can tailor these membranes to your specific needs. When you collaborate with them, you can harness the full potential of hollow fiber membranes.

Conclusion

All in all, hollow fiber membranes are not just microscopic tubes. They are also the best friends of filtration and separation.

In the aspect of medical procedures and research, its functions are unlimited. Under Google’s guidelines for clear, organized, and informative content, we can embrace these membranes. And it means embracing cleaner, safer, and more efficient processes.

The above is the information about the hollow fiber MBR membrane. If you still have questions about the membrane bioreactor or need to purchase MBR membranes, don’t hesitate to contact SPERTA.

Shanghai SPERTA Environmental Technology Co., Ltd. has specialized in producing water treatment products for many years. The company has the core technology of producing MBR membrane components. It has a high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world. If you have any needs, please feel free to contact us.