Advantages of the SPERTA UF-2880

Ultrafiltration Membrane

•High Strength and Durability: The PVDF material ensures high mechanical strength and resistance to chemical degradation. Regardless of harsh environmental conditions, SPERTA UF-2880 ultrafiltration membrane can operate stably and provide long-lasting filtration performance.

•Superior Anti-fouling Properties: The hydrophilic modification and outside-in flow configuration minimize fouling and ease maintenance, extending the membrane’s lifespan. Even in highly polluted water conditions, it maintains high filtration efficiency.

•Consistent Performance: Uniform pore size distribution ensures reliable filtration and high-quality permeate. In any application, SPERTA UF-2880 ultrafiltration membrane delivers consistent filtration performance.

•Versatile Use: Suitable for a wide pH range and diverse applications, from water treatment to biopharmaceutical processes. Whether it’s municipal water treatment, industrial wastewater treatment, or food and beverage separation and concentration, SPERTA UF-2880 offers excellent performance.

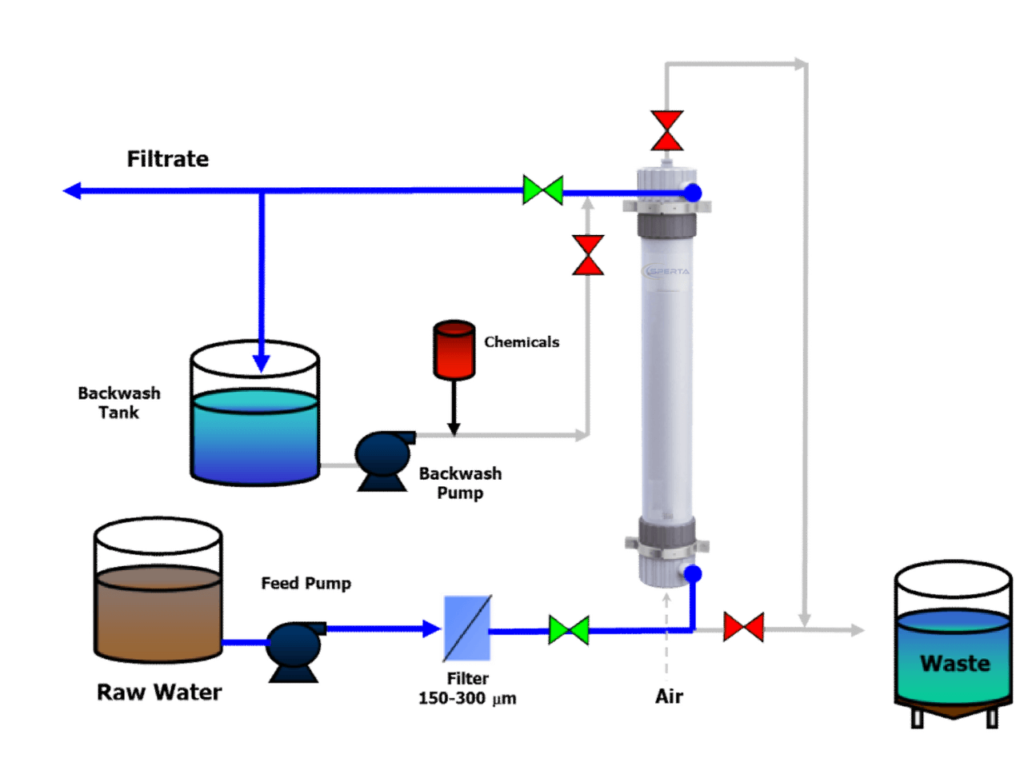

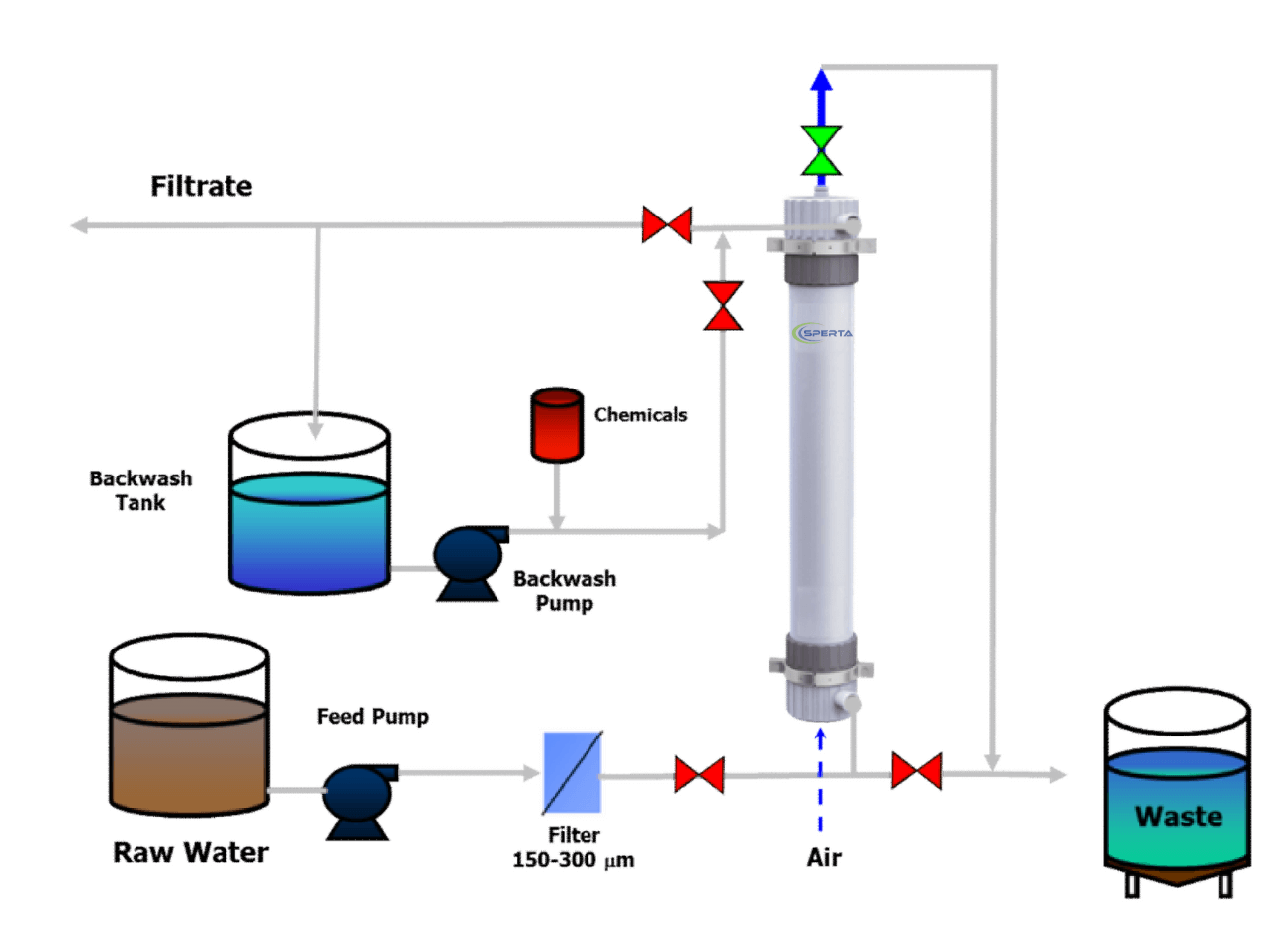

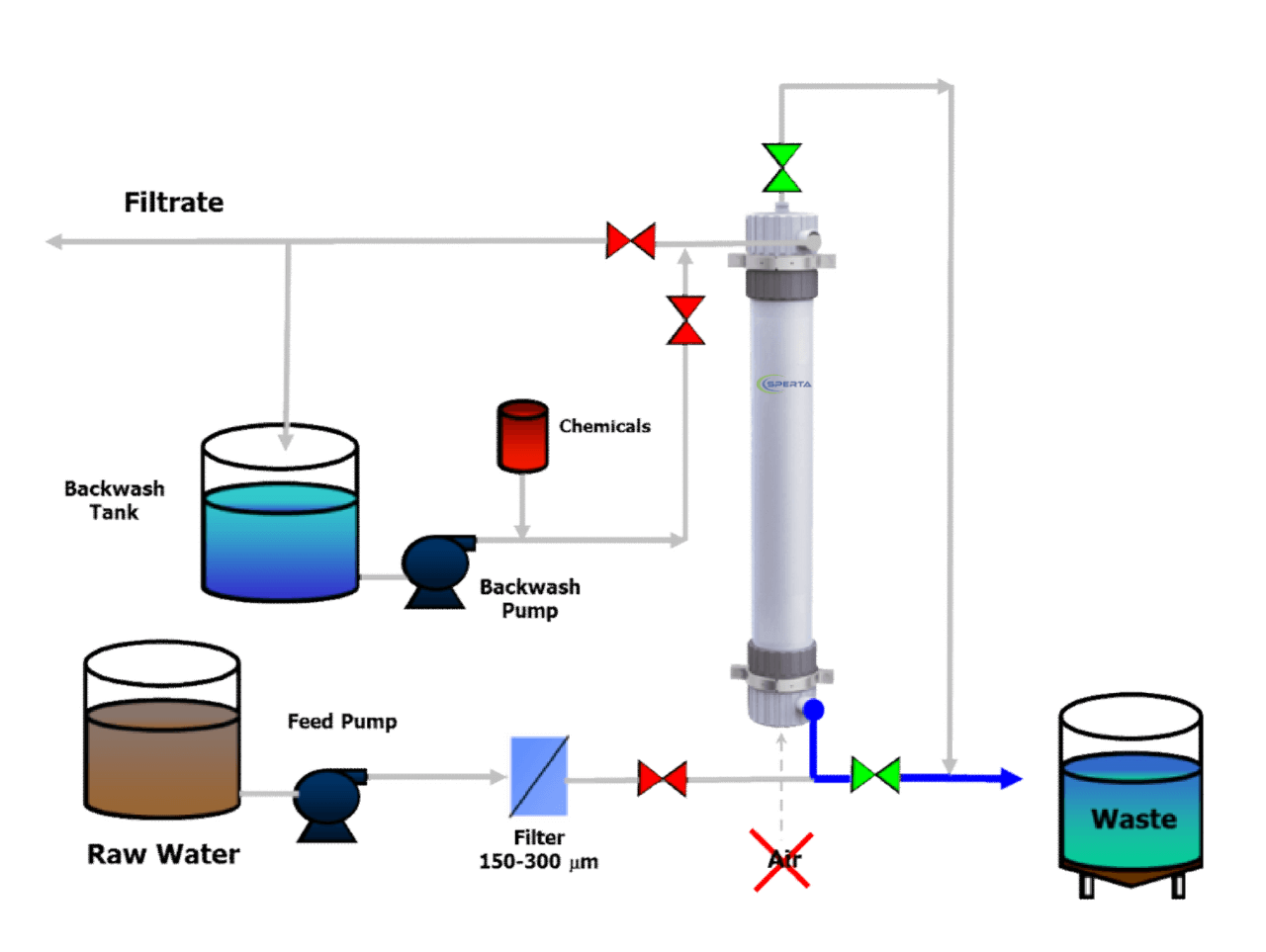

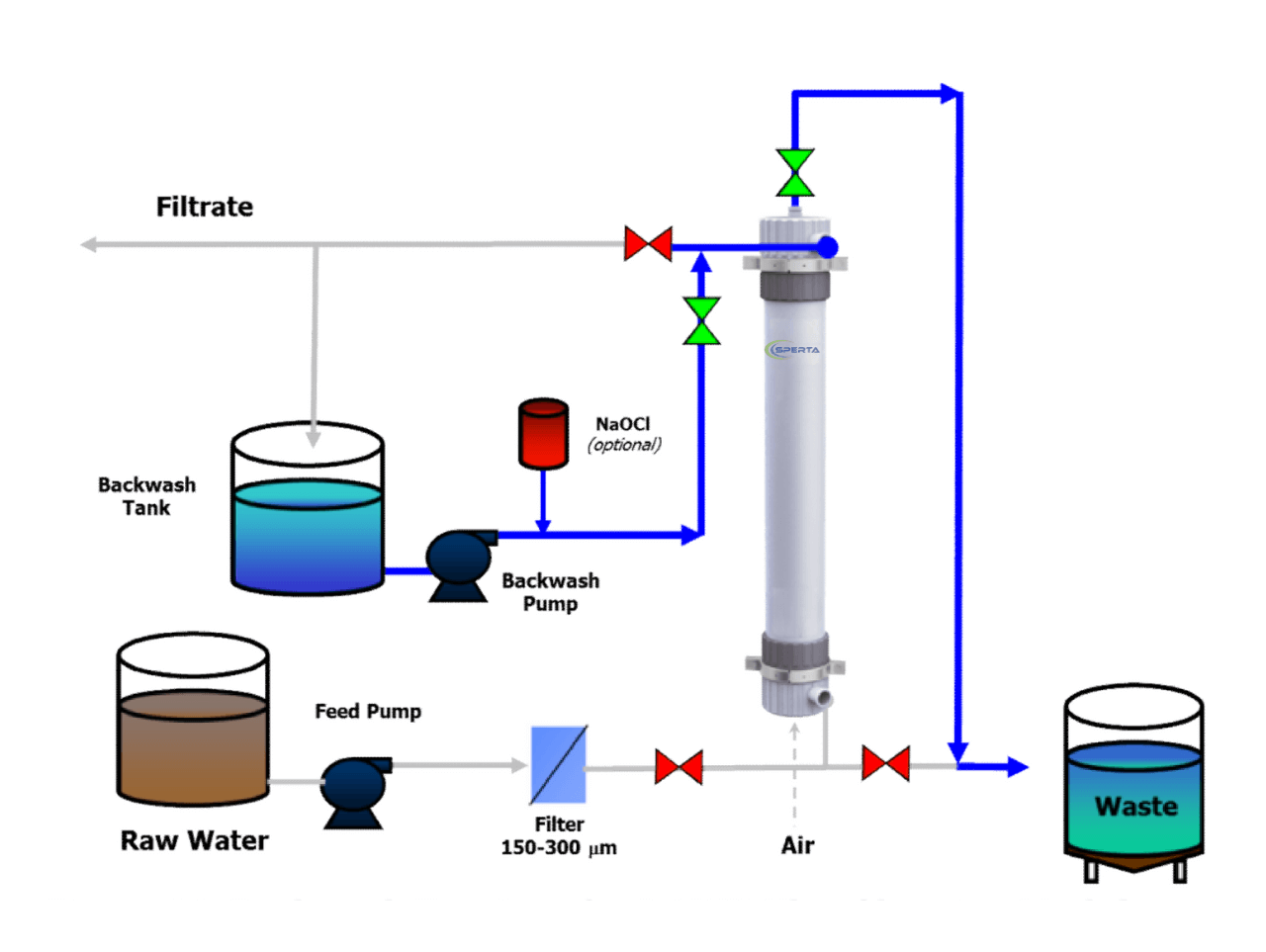

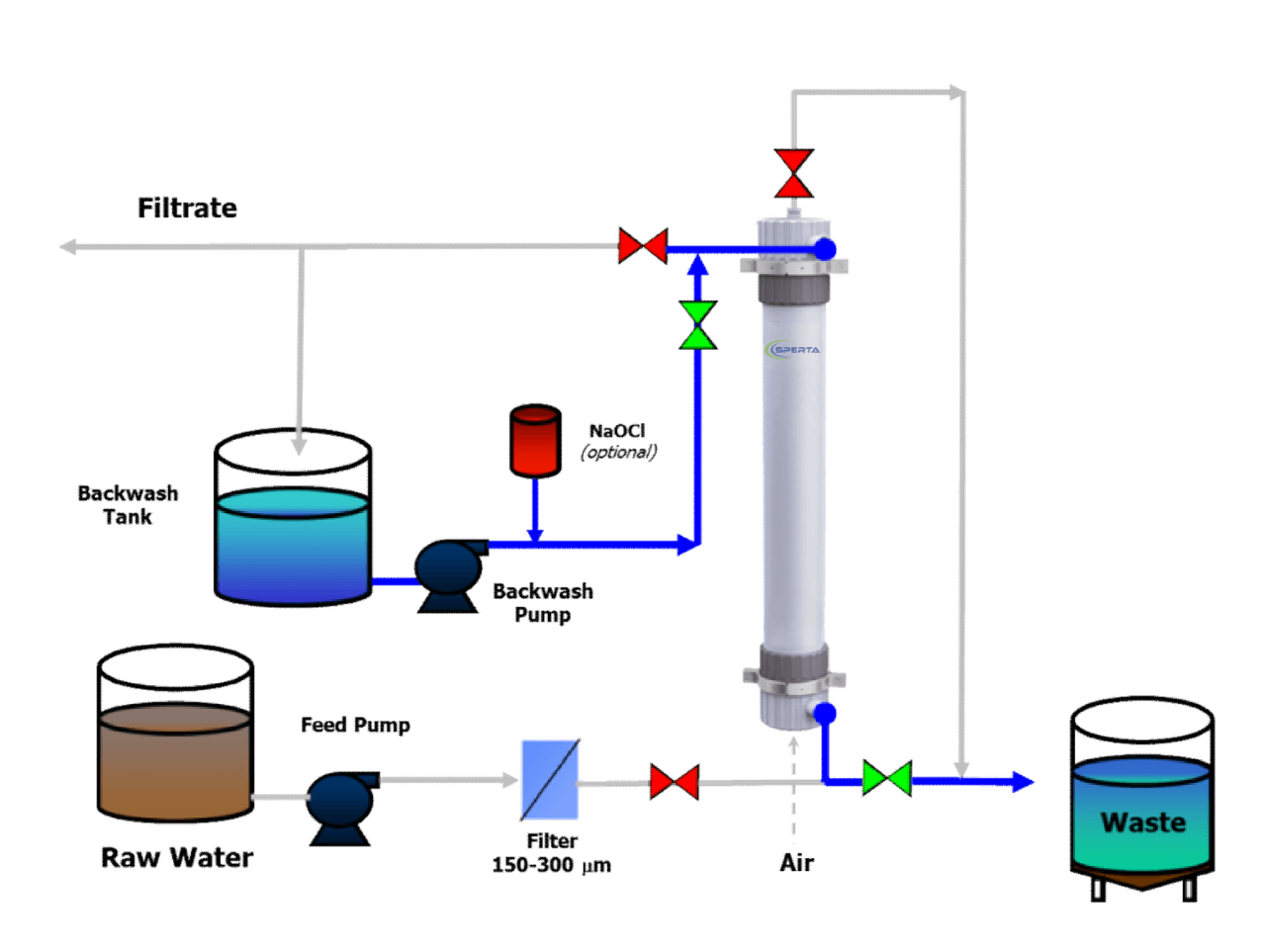

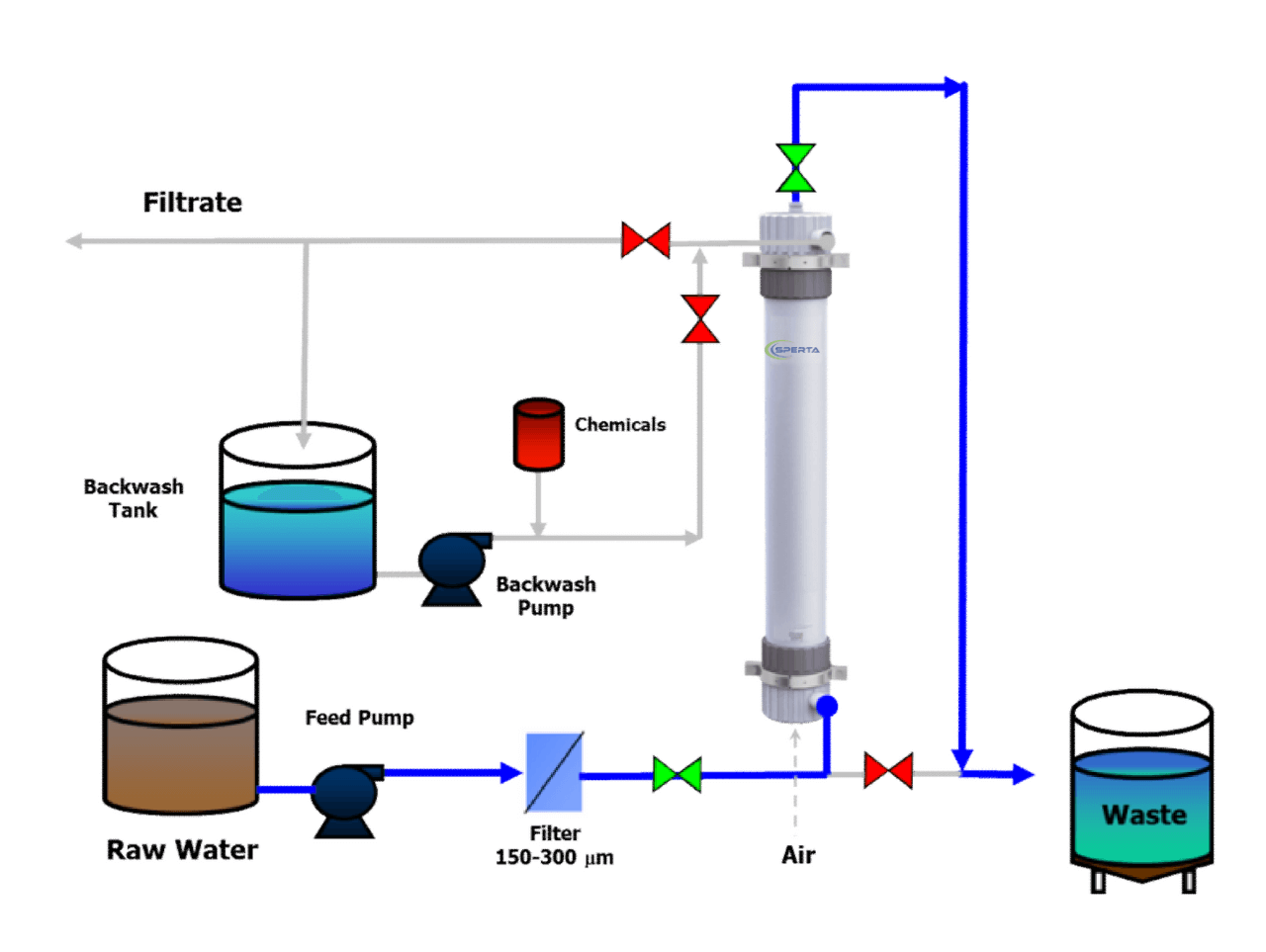

•Easy Maintenance: Simple and effective cleaning protocols, including water and air backwashing, extend the membrane’s operational life and reduce maintenance costs. Even under high-load conditions, it can be easily maintained to ensure stable system operation.

With its high strength, superior anti-fouling properties, consistent filtration performance, and versatile applications, SPERTA UF-2880 ultrafiltration membrane is ideal for water treatment and industrial use. Easy maintenance reduces costs and enhances system reliability and efficiency.