MBR is a new water treatment technology that combines a membrane separation unit with the biological treatment unit. It has broad application prospects.

MBR is mainly composed of bioreactor and membrane module. Sewage first enters the bioreactor. Pollutants are degraded by microorganisms in the reactor.

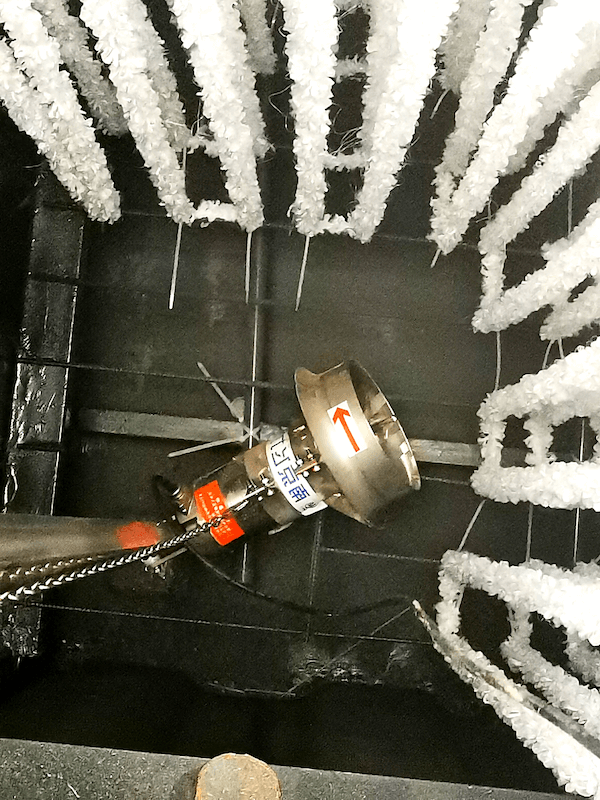

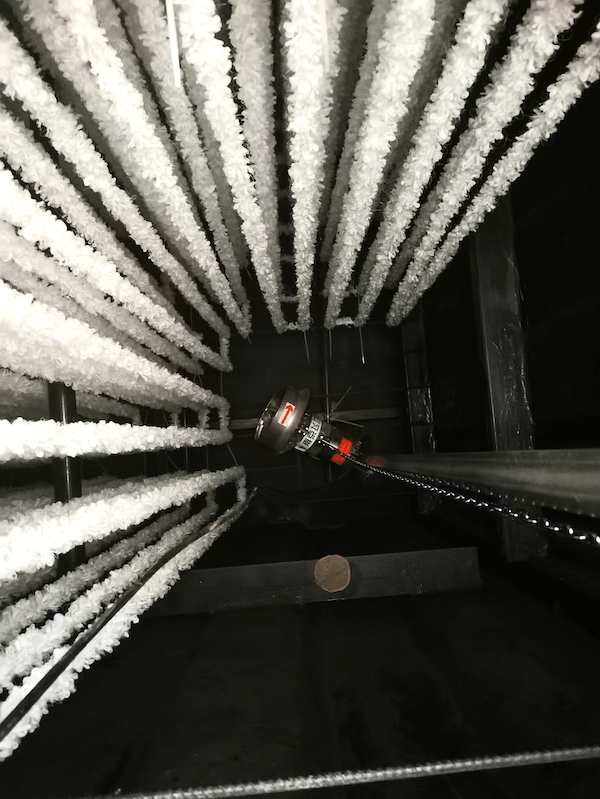

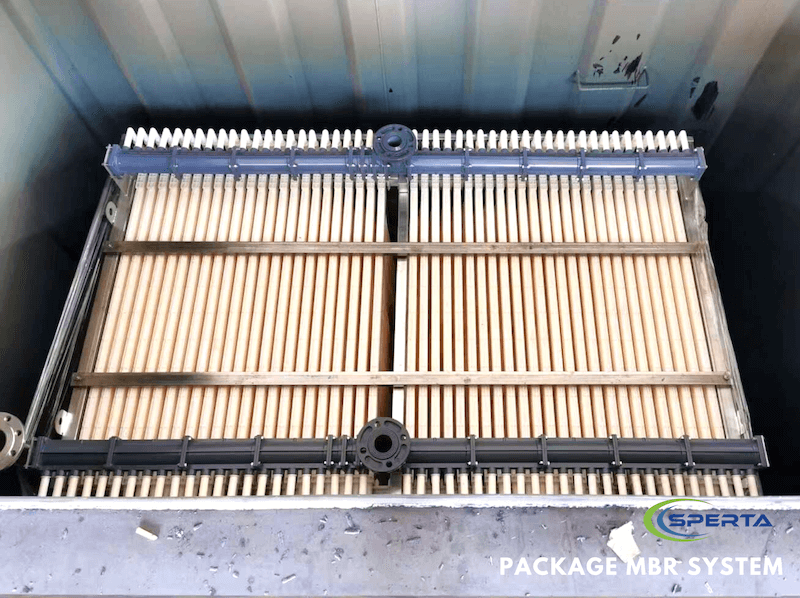

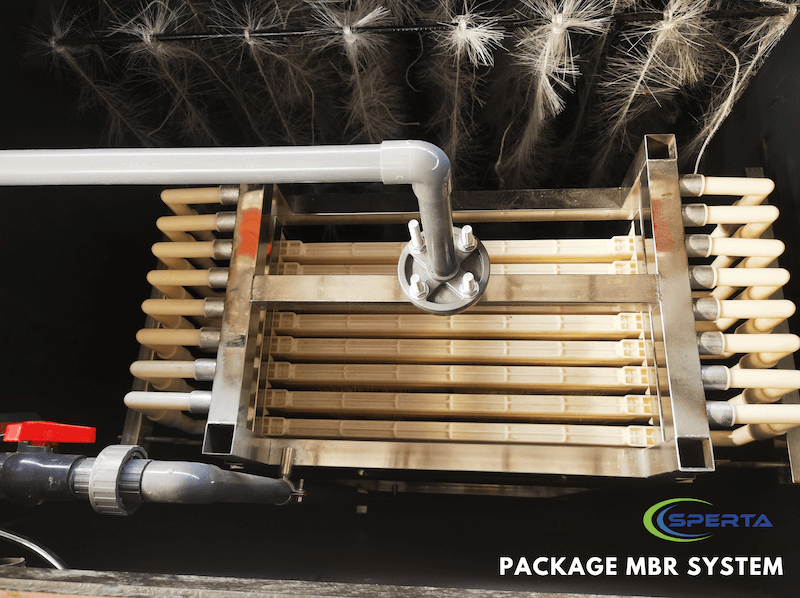

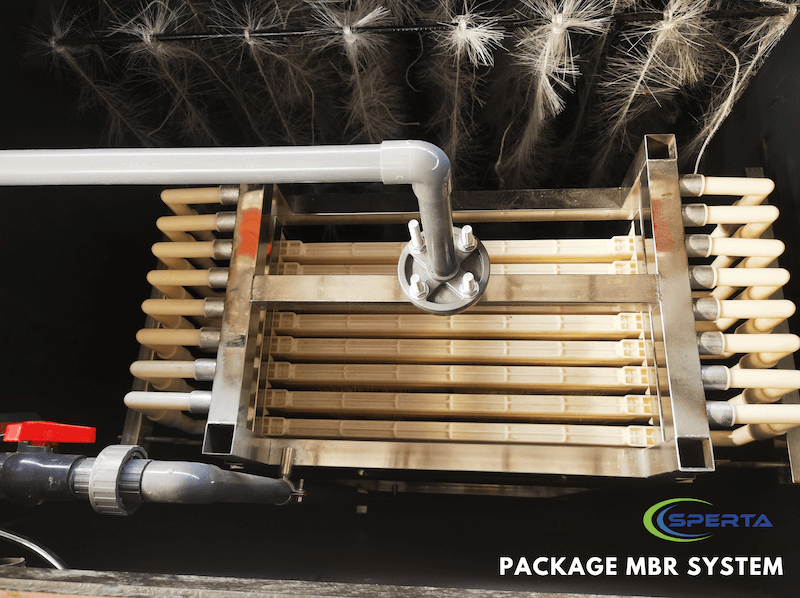

The membrane module is mainly used to intercept microorganisms and filter effluent.

Full customized MBR System wholesale

Fit well for your projects

100% high quality products

One-Stop Waste Water Treatment Solution

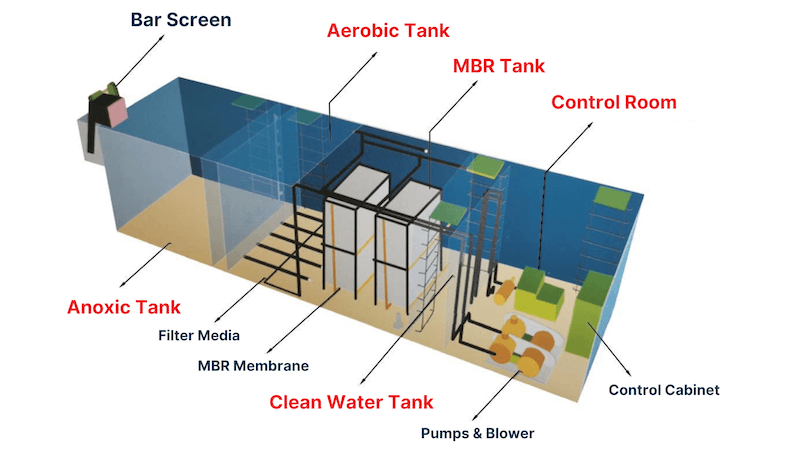

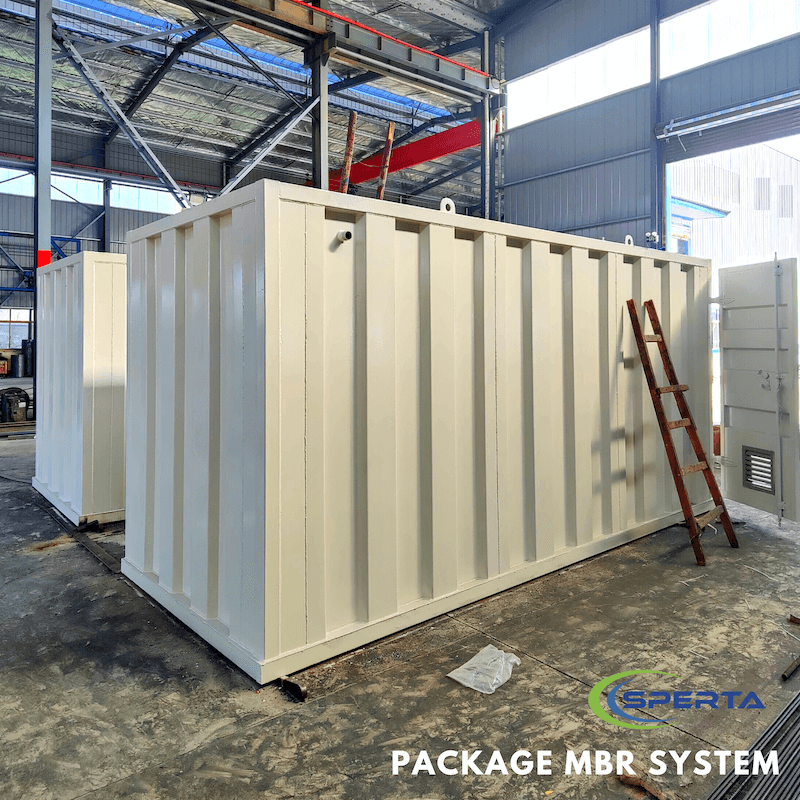

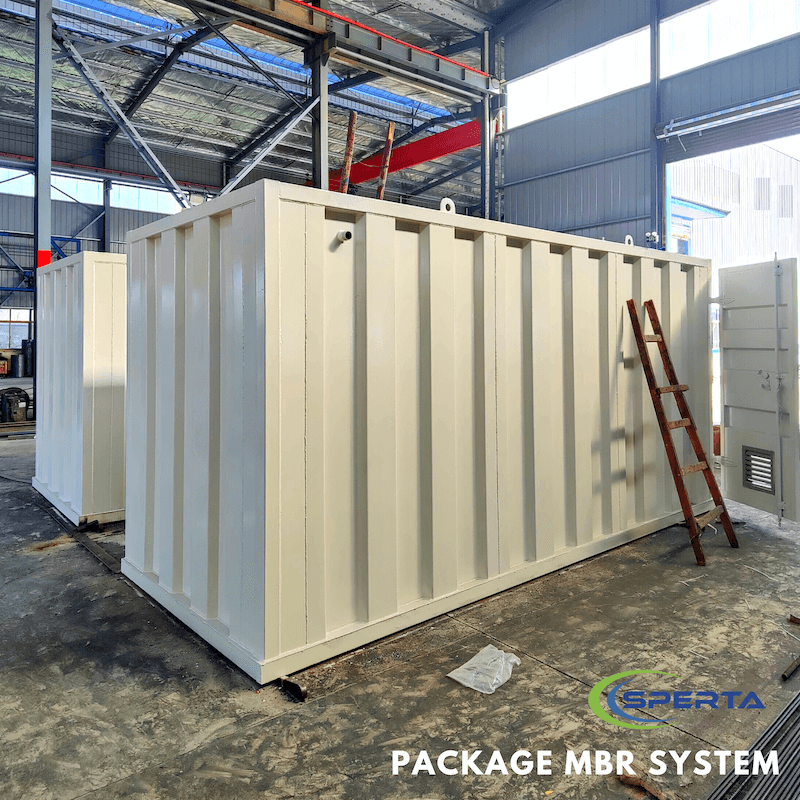

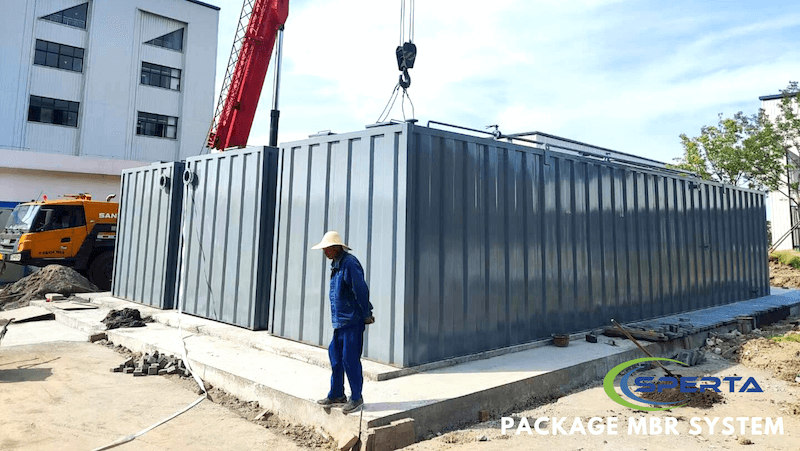

The package treatment plant consists of the adjusting tank, anoxic tank, aerobic tank, MBR membrane tank, and equipment room.

Compared with the traditional process, the package treatment plant can be fully automated, the management difficulty and risks are significantly reduced, and the operation is more stable.

After the raw water passes through the pre-treatment system to remove the large suspended particles in the sewage, it enters the anoxic tank for hydrolysis reaction. Composing macromolecular organic matter into small molecules under hydrolase improves sewage biodegradability.

It also provides a place for denitrification to reduce the total nitrogen content in the water. At the same time, biological phosphorus removal and chemical phosphorus removal are used to ensure the phosphorus content of the effluent meets the standard.

The effluent enters the aerobic tank, which is oxygenated by the air blower and decomposes the COD in the water under the action of aerobic microorganisms. The ammonia nitrogen (NH3-N) in the water undergoes a nitrification reaction to produce nitrate.

The MBR membrane module is mainly used to intercept microorganisms and filter the wastewater. The effluent enters the MBR membrane tank for solid-liquid separation to reduce the suspended matter content in the water.

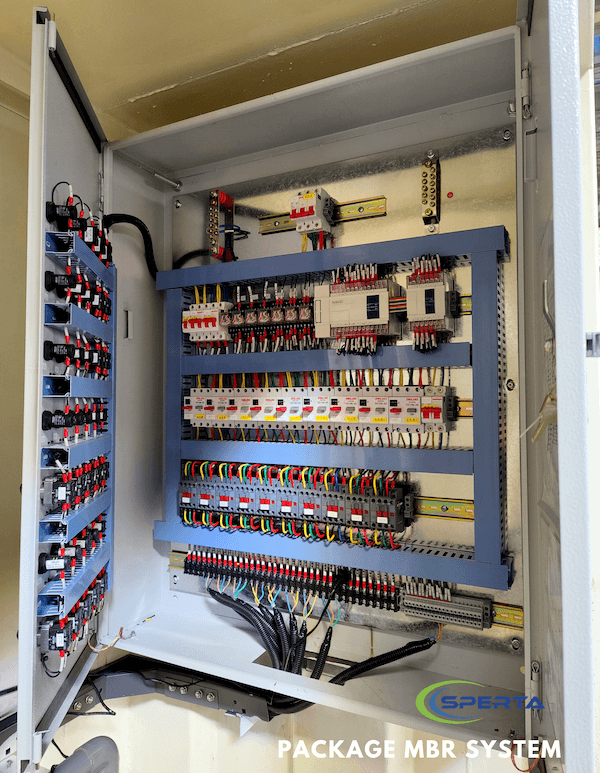

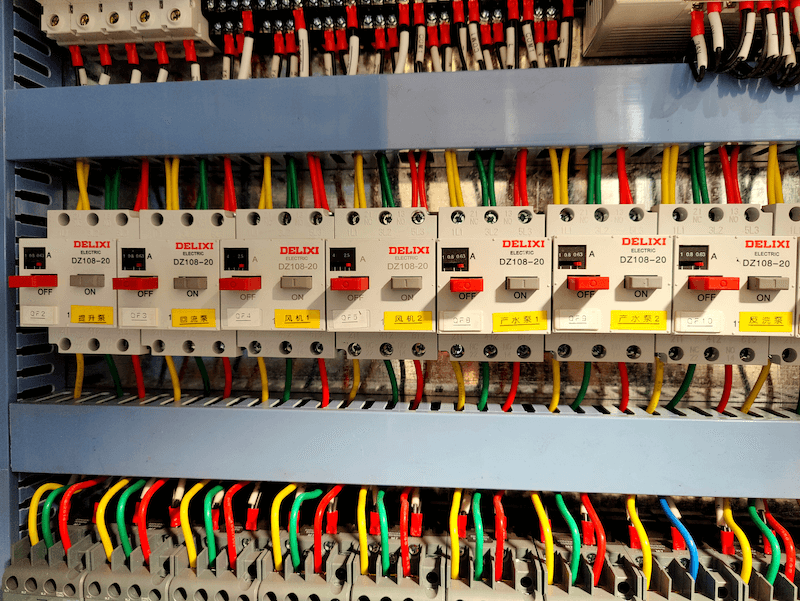

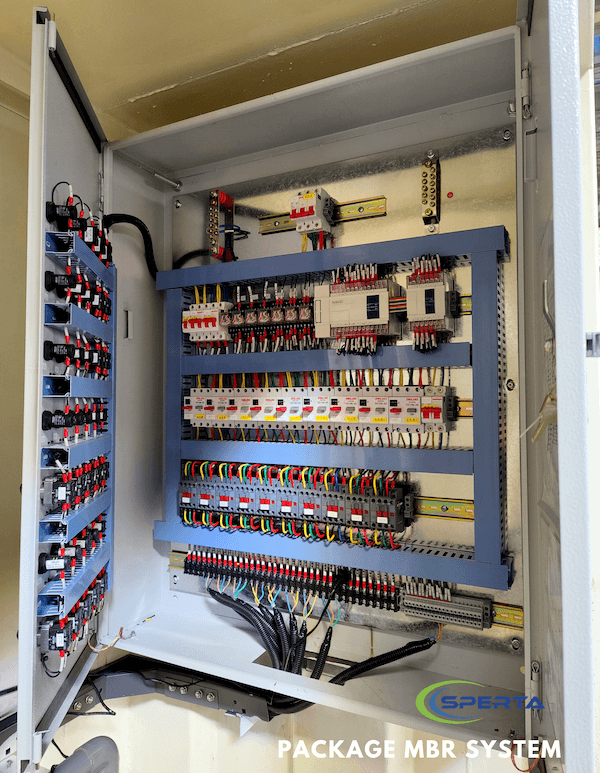

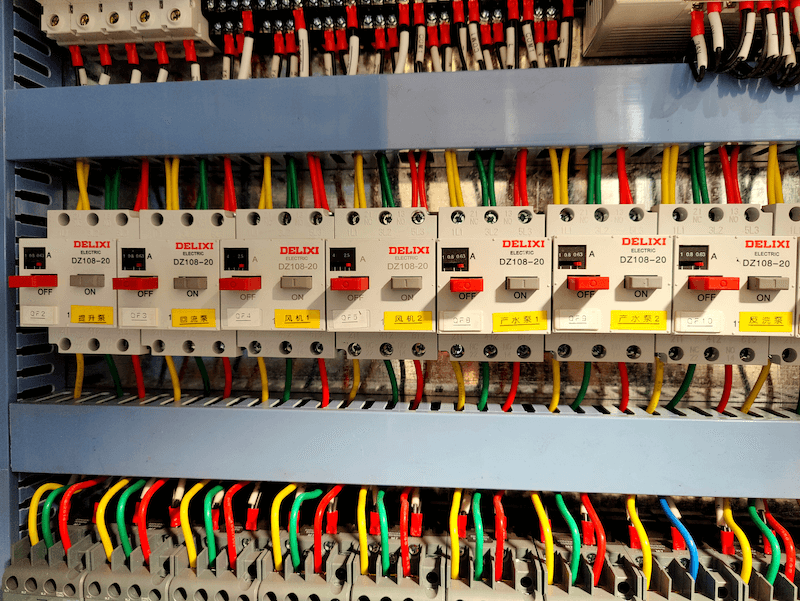

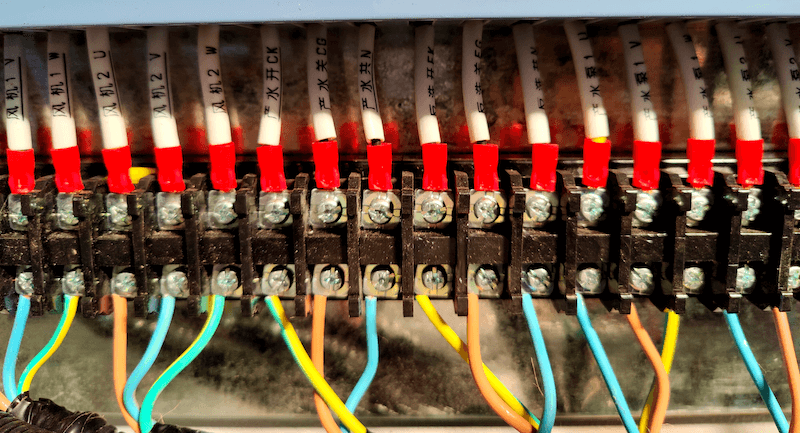

The equipment room is the place where the electromechanical equipment is placed. The equipment room has air blowers, suction pumps, PLC control cabinet, and UV disinfection and dosing equipment.

| Capacity | Model | System Size | Lift Pump | Air Blower | Suction Pump | Backwash Pump | UV Sterilizer | Dosing Pump | Power Consumption |

| 10m³/day | MBR-S-10 | 3.5*1.5*2.2m | 0.5m3/h | 0.2m3/min | 0.5m3/h | 1.0m3/h | 0.5m3/h | 9L/h | 0.87kw/hr |

| 20m³/day | MBR-S-20 | 4.5*1.5*2.2m | 1.0m3/h | 0.33m3/min | 1.0m3/h | 2.0m3/h | 1.0m3/h | 9L/h | 1.05kw/hr |

| 30m³/day | MBR-S-30 | 4.8*1.8*2.2m | 1.5m3/h | 0.63m3/min | 1.5m3/h | 3.0m3/h | 1.5m3/h | 9L/h | 1.25kw/hr |

| 40m³/day | MBR-S-40 | 6.0*1.8*2.2m | 2.0m3/h | 0.74m3/min | 2.0m3/h | 4.0m3/h | 2.0m3/h | 25L/h | 2.24kw/hr |

| 50m³/day | MBR-S-50 | 6*2.0*2.2m | 2.5m3/h | 1.09m3/min | 2.5m3/h | 5.0m3/h | 2.5m3/h | 25L/h | 2.6kw/hr |

| 60m³/day | MBR-S-60 | 8.2*2.4*2.2m | 3.0m3/h | 1.09m3/min | 3.0m3/h | 6.0m3/h | 3.0m3/h | 25L/h | 2.6kw/hr |

| 80m³/day | MBR-S-80 | 10*2.4*2.2m | 4.0m3/h | 1.39m3/min | 4.0m3/h | 8.0m3/h | 4.0m3/h | 40L/h | 3.7kw/hr |

| 100m³/day | MBR-S-100 | 11.5*2.5*2.5m | 5.0m3/h | 1.82m3/min | 5.0m3/h | 10m3/h | 5.0m3/h | 40L/h | 3.7kw/hr |

| 120m³/day | MBR-S-120 | 12.5*2.8*2.5m | 6.0m3/h | 2.29m3/min | 6.0m3/h | 10m3/h | 6.0m3/h | 50L/h | 5.5kw/hr |

| 150m³/day | MBR-S-150 | 13.5*2.8*3.0m | 7.5m3/h | 2.29m3/min | 7.5m3/h | 15m3/h | 7.5m3/h | 60L/h | 5.5kw/hr |

| 200m³/day | MBR-S-200 | 15.5*2.8*3.0m | 10.0m3/h | 2.66m3/min | 10.0m3/h | 15m3/h | 10.0m3/h | 60L/h | 5.5kw/hr |

100m3/day Domestic Wastewater Treatment

Standard (mg/L) | COD | BOD | NH3 | TN | TP |

Raw water | 350-500 | 180 | 45-55 | 30 | 6-9 |

Requirements | ≤30 | ≤6 | ≤1.5(2.5) | ≤15 | ≤0.3 |

Permeate Water | 26 | 4.7 | 0.58 | 8 | 0.11 |

360m3/day Domestic Wastewater Treatment

Standard (mg/L) | COD | BOD | NH3 | TN | TP |

Raw Water | 480 | 240 | 25 | 40 | 8 |

Requirements | ≤20 | ≤4 | ≤1(1.5) | ≤10 | ≤0.2 |

Permeate Water | 18 | 3 | 0.5 | 6 | 0.13 |

We are a high-tech enterprise specializing in waste water treatment industries. We have the core technology of producing MBR membrane components, and has high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world.

Factory Supply

Our factory has 2 production lines dedicated to the production of MBR Membrane.

Quality Standards

We have a very professional quality audit process after the the production is completed.

Great support

The staff you interface with are experienced and certified in their English language skills.

Design on Demand

You provide the project information and we generally will give you a solution.

At SPERTA, we take pride in the strong relationships we’ve built with our clients. Our commitment to quality and service has earned us the trust of numerous businesses worldwide. Here are some moments captured with our valued clients, both in our office and at various exhibitions. These interactions not only strengthen our bonds but also provide us with valuable insights to continually improve our products and services. Join the SPERTA family and experience the difference.

At SPERTA, we are proud of the recognition we have received for our commitment to innovation, quality, and sustainability in the field of MBR technology. Here are some of our notable achievements:

Patented Technology: Our unique, patented MBR technology underscores our commitment to innovation and industry leadership.

Quality Certification: Our ISO 9001 certification attests to our rigorous quality management and dedication to continuous improvement.

Sustainability Recognition: Our MBR membranes have been recognized for their role in reducing environmental impact and promoting water conservation.

Customer Satisfaction: With a consistent customer satisfaction rate above 95%, we are committed to exceeding customer expectations.

These achievements are a reflection of our team’s hard work and dedication. They motivate us to continue striving for excellence and to keep pushing the boundaries of what is possible in our industry.

Sperta has been wholesaling MBR Systems for 12 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

We are the manufacturer and the trading company. We have professional manufacturing teams and a strong oversea sales team.

Our factory locates at Suzhou, near shanghai. Welcome your visits to our factory. Our office is in Shanghai and we export goods from Shanghai or Guangzhou ports.

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

At least 3 years warranty. Meanwhile our team will provide you continuously after-sales services.

Depends on the speed of customs clearance and logistics, but we can guarantee to ship to you within 15 days after deposit received.

Please contact us through distributor page, we are very willing to discuss distributor program with you.

We are glad to provide you free samples, just send us a message.

We can accept T/T, L/C, Western Union, Paypal, cryptocurrency and so on. For new customers, we only accept the 30% T/T of the payment, or if you have been with us for years and run into cash flow pressure, we do offer OA credit.

Sperta have been in the business of wholesale MBR Membranes in China for 12 years, let a true industry veteran provide high quality MBR Membrane for your projects.

We will contact you within 6 hours, please pay attention to the email with the suffix “@spertasystems.com”.