Last Updated on July 24, 2022 by Kevin Chen

There are many different wastewater treatment systems available on the market today. Membrane bioreactor (MBR) is one type of system that is becoming increasingly popular due to its many benefits.

What is MBR Membrane and How does it work?

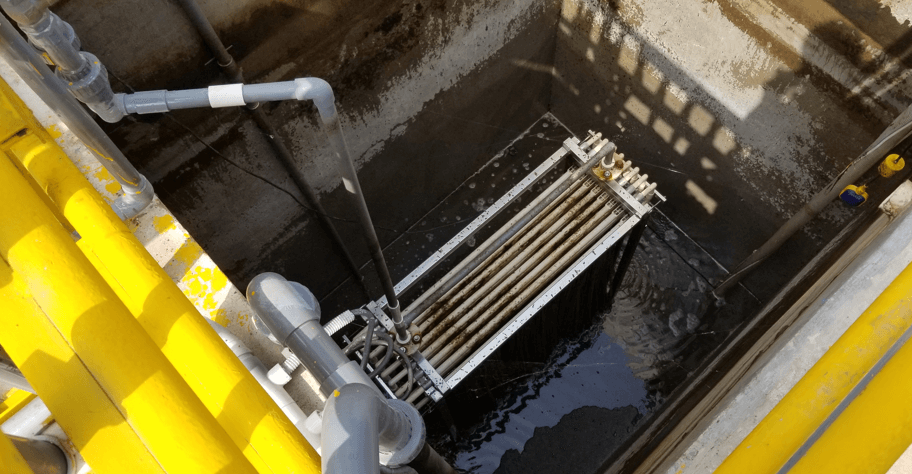

MBR membrane is a type of membrane technology used in water and wastewater treatment. It is a type of MBR system that uses an activated sludge process to treat wastewater. The key difference between conventional activated sludge systems and MBR systems is the use of an anaerobic membrane bioreactor (MBR), which allows for the separation of microorganisms from the treated effluent. MBRs have become increasingly popular in recent years because they can produce high-quality effluent while minimizing environmental impact.

Membrane Bioreactor (MBR) is the Future of Wastewater Treatment

In wastewater treatment, membrane bioreactors (MBRs) have begun to replace activated sludge systems for a number of reasons. MBRs are more efficient because they use less energy and can handle higher BOD loads. Additionally, MBRs produce less sludge and can be operated at a higher pH without compromising performance. Finally, MBRs can easily be adapted to accommodate fluctuations in flow and loading, making them an attractive option for municipalities with changing needs.

Advantages of MBR Membrane

MBR membrane technology is widely considered to be the best wastewater treatment option available. This is because MBR offers a number of advantages over other methods, including:

- Increased removal efficiency – MBR systems can achieve much higher removal efficiencies than traditional sewage treatment plants, making them ideal for use in areas with strict environmental regulations.

- Reduced footprint – MBR systems are much smaller than traditional sewage treatment plants, making them perfect for use in tight spaces or where land is limited.

- Smaller footprint – MBR systems take up less space than conventional wastewater Treatment facilities, making them ideal for use in densely populated areas or for small operations.

- Reduced sludge production – The separation process of an MBR removes more organics from sewage than a conventional activated sludge process, resulting in up to a 50% reduction in sludge production.

- Improved effluent quality – The finer filtration produced by an MBR can mean higher quality effluent water that can be discharged without secondary treatment or used for irrigation and other purposes.

Conclusion

This article has explored the benefits of membrane-based wastewater treatment, specifically MBR membrane technology. MBR membrane systems are more efficient and require less space than traditional wastewater treatment systems. They are also more environmentally friendly, as they use less energy and produce fewer pollutants. For these reasons, MBR membrane technology is the future of wastewater treatment.